Flat surfaces are the most common type of thing to use in a laser engraving machine. When it comes to laser systems, their focus method is designed to function around a set of coordinates positioned on a two dimensional plane. This is a fundamentally sound design, and as long as the materials you are working with have a two dimensional surface (a.k.a. flat surface).

Engrave on a Round Object: Introducing the Laser Engraver Rotary Attachment

Using a laser engraver with rotary attachment isn’t a new concept, but when it comes to desktop laser engravers, there aren’t many out there that offer the compact versatility of the Muse Series desktop laser cutting and engraving machines. With the Rotary Riser attachment for the Core and 3D Autofocus models of the Muse series, the ability to keep a safe and enclosed laser engraving machine while also using a rotary attachment is now possible.

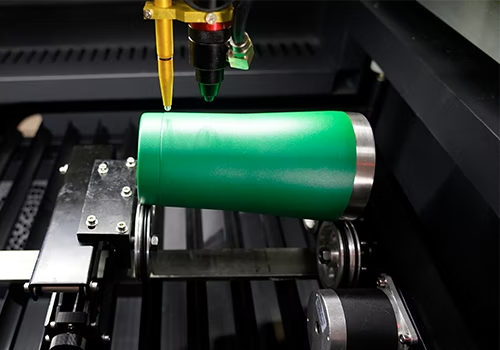

For many laser cutter and engraving machines, keeping the system enclosed while using a rotary attachment can be challenging. But with the patented removable floor feature of Muse series laser cutting and engraving machines, it's easy. Simply replace the removed floor with the riser attachment. This riser is designed to elevate the gantry system and provide an extended height on the Z-axis. This extended height allows for a friction rotary system to sit safely inside a fully enclosed machine. This setup will allow you to use your laser engraver for tumblers and other round or cylindrical objects that are up to four and a half inches in diameter.

What if you have a cup, or other round object, that is more than four and a half inches in diameter?

Once again, this is where the patented removable floor comes into play. You can elevate the Muse Core or Muse 3D Autofocus with blocks or bricks to an even higher position to allow for larger diameter objects to fit on the rotary. Since it is a friction based rotary system, there is no need to worry about calculating the diameter in the software.

Once again, this is where the patented removable floor comes into play. You can elevate the Muse Core or Muse 3D Autofocus with blocks or bricks to an even higher position to allow for larger diameter objects to fit on the rotary. Since it is a friction based rotary system, there is no need to worry about calculating the diameter in the software.

Beyond the Core and 3D Autofocus versions, the rest of the Muse series of desktop laser systems can also work with a rotary system. The Muse Titan has the same patented removable floor and can fit a friction rotary inside without the need for a riser, and the Muse Galvo systems (both the Fiber laser and UV laser variants) have both friction style and chuck style rotary attachments available.

With the ability to engrave fine details on the Muse Fiber Galvo laser machine, and extremely fine details on the UV laser, you can engrave on much smaller objects such as jewelry. There is a chuck rotary attachment available for these systems that is specifically designed to grasp either the inside or outside of a ring. You can get amazingly detailed engravings on metals (including seamless results on both gold and silver), so being able to customize rings will give that extra personal touch to a precious item. The specialized chuck rotary that is used for this can also rotate at an angle, allowing you to engrave even the inside of the ring. And the UV laser works great on marking these metals, so you can get even finer details on the thinnest of rings.

Beyond the Desktop Laser Cutting and Engraving Machine

Whereas the Muse series excels as desktop laser cutting and engraving machines, the P-Series laser systems take everything to the next level. With the heavy duty chassis and increasingly larger workspace sizes, the P-Series is the best option for those who deal with increasingly large production volumes and need to have it running frequently throughout the working week. This need for higher volumes and the need for faster production is also incorporated into the rotary attachment as well.

Whereas the Muse series excels as desktop laser cutting and engraving machines, the P-Series laser systems take everything to the next level. With the heavy duty chassis and increasingly larger workspace sizes, the P-Series is the best option for those who deal with increasingly large production volumes and need to have it running frequently throughout the working week. This need for higher volumes and the need for faster production is also incorporated into the rotary attachment as well.

The rotary attachment for the P-Series laser systems comes in either a friction or chuck style option. These rotary attachments for the P-Series plug directly into the Y-Axis motor port with a screw-type connector. This supplies the rotary with a more solid connection that will not risk coming detached while jogging the z-table or when running the job.

So whether you are running the rotary on a desktop laser cutter and engraver system in the Muse Series, or if you are involved with high-speed productivity and increased volume sizes in the P-Series laser systems, there is a rotary option available to give your system even more capabilities.

A rotary attachment is just one of the many options available to increase the capability of your laser cutter and engraver. If you aren’t sure what you need to meet your specific applications, then feel free to contact us at any time. We want to make sure you get set up with exactly what you need to help keep your process going and increase your return on that laser investment.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.