Laser Vector: What is it?

When it comes to the laser terminology and how it applies to your laser cutter and engraver, the word “Vector” is a word that comes up quite frequently. When discussing laser vectors, there is a specific definition that can be applied, though there is more than just that. The word “vector” itself has several different meanings depending on how it is used. So we will go into detail about what laser vector is and how it relates to your laser process.

Laser Vector: Vector vs Raster

When you are using your laser, there will be two different types of functions that your laser will translate onto your material, vector and raster. Understanding the difference between these two terms will help you determine what your project will utilize, and how you will get your laser set up to function for that specific project. To simply put it, laser vector will be when you use the laser machine to make cuts and lines, and laser raster is when you will be engraving designs and images.

Laser Vector: Vector in Physics and Mathematics

The term “vector” isn’t exclusive to laser cutters and engravers. In fact, the term is more widely used in the fields of mathematics and physics. Though, understanding how this term applies to these fields will help you better understand how you use a laser vector.

In mathematics and physics, the term “vector” is used to reference quantities that can’t be expressed by: a single number or, to individual elements of some linear spaces. To utilize this information so you can understand what a laser vector is, just boil the term down to its basic variables such as direction and magnitude, which can be quantified by force and velocity.

Laser Vector: Vector Graphics

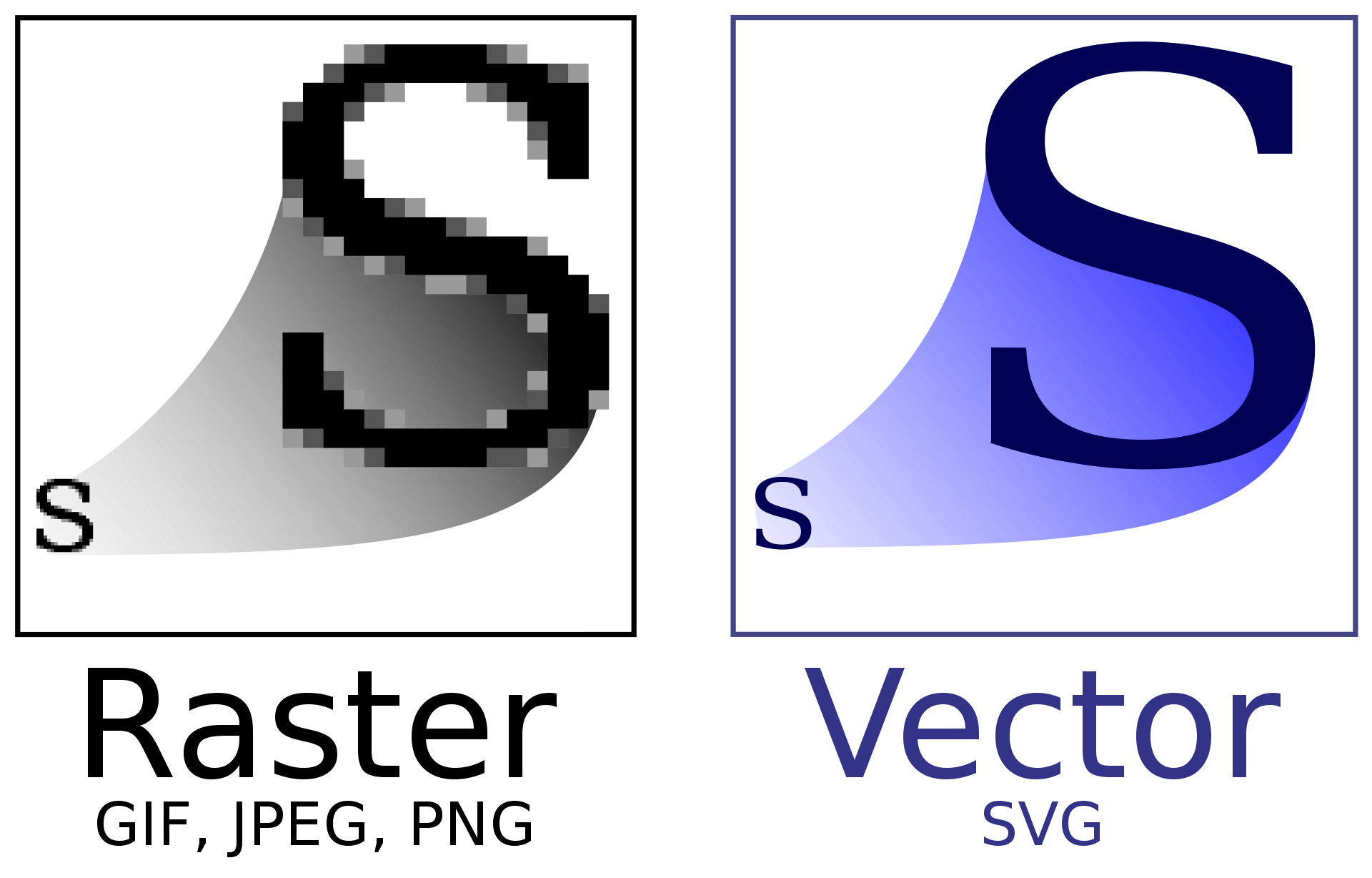

The term vector is also used in graphic design. Vector graphics are a form of computer graphics: a set of mechanisms and values for creating visual images on a two dimensional plane using points, lines, and curves. Graphic design software such as Adobe Illustrator, or Inkscape, use this information to manipulate and visualize vector graphics. Designs that you create using these programs can be transferred to your laser control software, where they will be converted and utilized as a laser vector. Your designs will need to be saved as a type of file that will maintain your vector graphic information. Because the information or data stored isn’t based per pixel, but instead is based on the lines and how they function, this type of file can be scaled indefinitely without worrying about loss of detail or degradation.

Image source: Wikipedia

Common vector graphics file types:

- SVG: This is the most standard file type that most programs will be able to export as

- DXF: Most commonly used with computer aided design software (CAD).

- PDF: This stands for “Portable Document Format,” and you will probably have used this file type before. It not only stores document information securely, but will also save imaging information for laser vector graphics.

While there are other file types out there that store the vector information, these are the most common files that are used. The laser cutter and engraver can work with other file types, such as JPEG and PNG, but these only save data that essentially tells the properties of each pixel as opposed to including information that can be used for laser vector graphics. In essence these files are more commonly used for raster engraving instead.

Laser Vector: Applying to Laser Control Software

Now that we have covered the essentials of what a vector is, it is easier to describe how this applies to laser vector graphics and how they are utilized by the laser cutter. The laser machine uses a gantry that can move the laser head to any point in its workspace, represented by a two dimensional plane. Once the vector graphic has been imported into the laser control software, it will convert it so that the information can be output as a physical representation of the laser vector.

When it comes to engraving, some advanced laser control software platforms like RetinaEngrave v3.0 (RE3) provides the ability to convert your laser vector into a raster. This is useful if you want to engrave small details and aren’t sure of the exact size you need. Remember if you use a laser raster file, such as JPEG or PNG, you can lose file quality as you size it. Therefore it can be a benefit to use a laser vector file for sizing first and then convert it to a raster file before the final engraving. Keep in mind, this won’t be possible for detailed photos, but it is great for graphics and logos. You can also take a JPEG or PNG logo, and use the trace feature to turn it into a laser vector. This feature can be beneficial for cutting the outer edge of an engraving. You can even adjust the tolerance of the tracing to get further details from within the file that is being traced.

Understanding the difference between laser vector (cutting) and laser raster (engraving) will aid you in creating projects with that perfect balance between components that are cut and components that are engraved. Experiment with these ideas and learn from trial and error. You’ll be on your way to becoming a true laser expert.

Full Spectrum Laser is a leader in easy to use, highly versatile laser cutting and laser engraving machines. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.