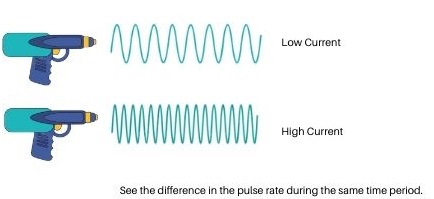

There are a lot of terms that are thrown around when we discuss how to get the best results with a laser cutting machine. Two important terms we will highlight in this article are laser cutting machine power and current. If you can think of the laser tube like a gun, the current output by a laser is going to be comparable to the number of bullets that would be shot out by a gun. When you're on high current you're shooting a lot of bullets, it’s a high pulse rate. Laser power in the context of the gun is the size of “bullets” which are being fired out. Higher power is going to remove more material from the surface of the object you’re using a laser on. Keep in mind, these terms are only going to refer to cutting (or vectoring) because the engraving (raster) setting has a set current that is not able to be adjusted.

What laser cutting machine power and current settings mean for you

Let’s dive deeper into what these laser cutting machine power and current settings mean for you as you create your projects.

The laser cutting machine power setting is a digitized measurement of the intensity and the amount of pure energy that's coming to the machine. The spot size of the laser beam and the rate at which the beam is fired both stay consistent. The power setting is used to adjust how much energy is leaving the CO2 laser tube once you click “run job.” Laser cutting machine power setting is the more coarse, broad spectrum, measurement so you’ll want to adjust this number first before you touch the current. Just like a microscope, you’ll want to use the coarse focus first then move into fine tuning to get the perfect settings for your specific job. If you do it the other way around, the process can take much longer. Plus it will be difficult to know if it is the power or current that needs to be changed should you not be happy with the output.

Laser cutting machine current is going to be the term used to describe the pulse rate of the laser: how many times your laser is firing within the duration of the job. Depending on what software system is installed on the laser you have, it can be represented in the software under the terms “frequency” or “pulse rate.” Current and power will correlate in most cases, so you’ll most often be changing both of these numbers up or both of them down. Once you adjust the power up or down, you’ll want to do the same to the current until you get the results you’re looking for.

What does this mean when you want to run a job?

Knowing these terms and how they work together will be useful when you need to do some troubleshooting with your laser projects. It can be difficult to conceptualize the finished project you want to see and then work backwards in the software settings to achieve the desired effect.

Let’s consider this common scenario: You’re getting charring on the edges of your material and you know that if you lower the power down any more, the laser won’t be strong enough to cut through. This is ideal since you want to use your laser at the lowest power required to reliably complete the job and maintain the integrity of the CO2 laser tube. As a result, we know we have the correct amount of power, so the next step is to lower the current by a small bit and run a test, either on paper or on a scrap piece of the same material you want the final design to run on.

Always keep in mind, laser cutting machine power and current settings will usually correlate as mentioned earlier in this post. Remember this if you get lost in finding the right settings and need a place to start. This helpful tip is true for CO2 lasers of any brand and any wattage of tube like the Muse Titan.

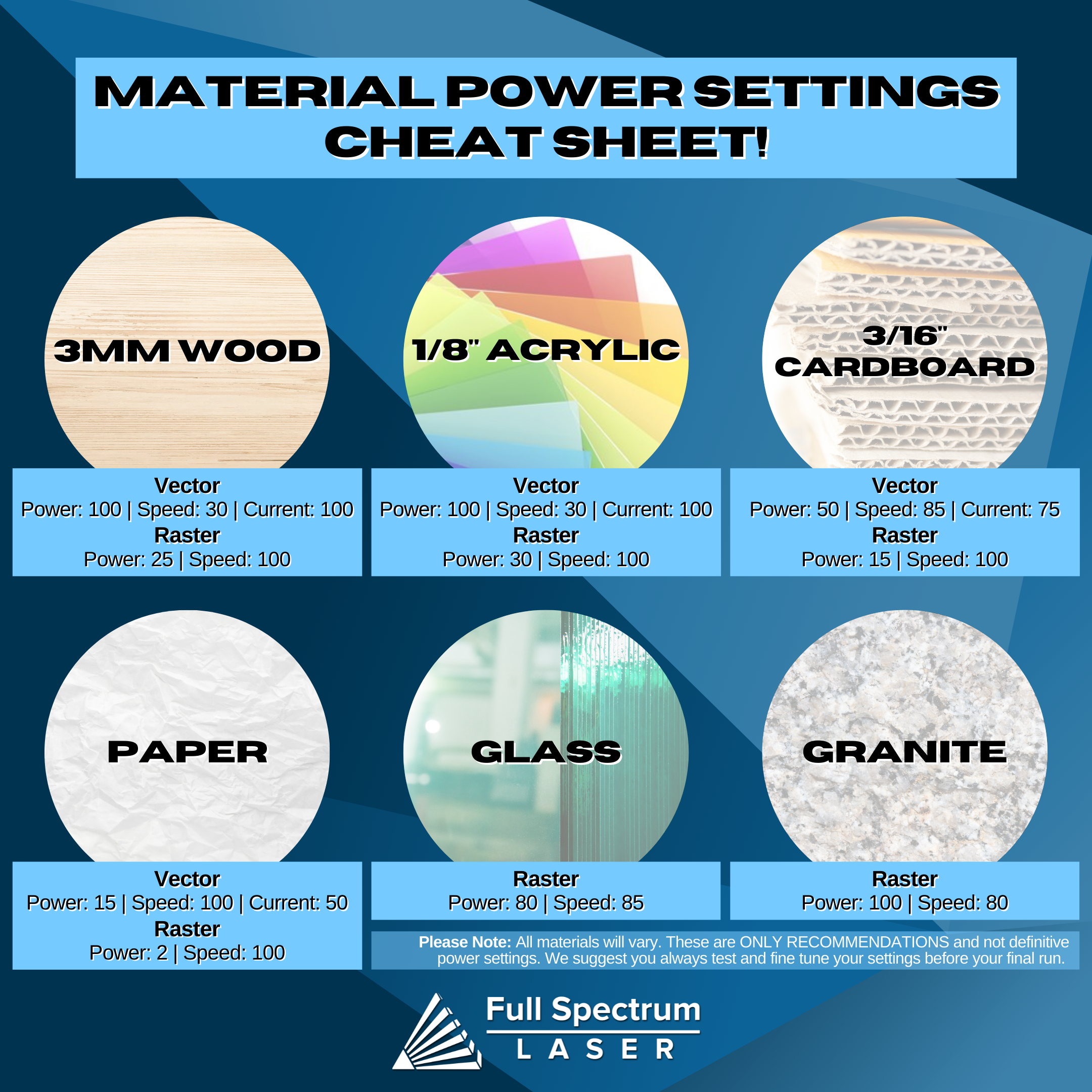

As you look for the optimal laser cutting machine power and current settings, here’s a quick reference guide that you can use as a place to start. This is just one example of the wide range of resources we have available to help guide you with your laser projects.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.