3D Camera and Motorized Autofocus: Desktop Laser Cutter Advantage

One of the most valuable features for advanced desktop laser cutting and engraving machines like the Muse Series is the motorized autofocus. This feature is highly convenient and can significantly increase productivity and consistency. Not only is this feature convenient, but it is aided by the 3D Camera which gives the video even more accuracy. Plus the 3D camera comes with many other features that will provide even more control over your laser cutting and engraving machine (whether it is the CO2 laser, Fiber laser, or UV laser).

Advanced desktop laser cutting and engraving machines that come standard with the 3D Camera and Motorized Autofocus can optimize your project efficiency. The 3D camera aids your laser cutter and engraver by giving it essential height data, which it then sends to the laser and its software to use to make sure your motorized autofocus adjusts to the correct height every time.

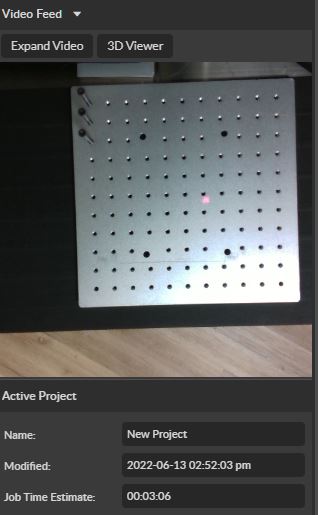

With a Muse series desktop laser cutting and engraving machine, the 3D camera is able to take a photo of your workspace and give an accurate representation of it in the included RetinaEngrave v3 software (RE3). Having a perimeter function is handy, but it just outlines the object with a square, so it can leave you guessing, which means you have an increased chance of the engraving not lining up exactly where you’d like. But with a 3D camera’s workspace capture, you can line up your design onto the object, and it will engrave or cut exactly where you place it. This can save you a lot of time in lining up the design, and it will save you money by making sure it will be correctly placed the first time.

Instead of having to manually crank and adjust the z axis and hope that you dialed it into the correct height, a desktop laser cutting and engraving machine with motorized autofocus and a 3d camera will take care of it for you, as well as being much quicker. When it’s time to cut or engrave, the 3D camera accurately maps millions of 3D data points which the laser utilizes to adjust the Z motor so the laser head is focused to the correct height.

How to take advantage of these features

With a Muse series desktop laser cutting and engraving machine, the included RE3 software enables you to set different focus points that will tell the laser exactly where you would like it to focus. And if you want to get even more advanced, you can use this feature to map out multiple points in your workspace, and the laser will automatically adjust to match those specific points as it gets to that portion of the job.

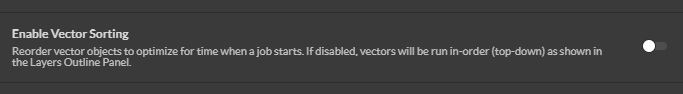

These will be associated with different layers (which can be sorted by color), and then via the vector sorting options, it will adjust for each of those points in the order that they are laid out. Make sure the automatic vector sorting option is disabled in your settings so the laser will follow your layered order.

Once your laser is running its job, you can either monitor it directly by looking at it (just make sure you take the proper safety precautions and wear the correct safety glasses), or you can view the live feed from the camera.

For example, let's say you are using a Muse Galvo Open fiber laser and two people want to watch but you only have one pair of safety glasses. The person without the safety glasses can avert their eyes from the light generated by the laser and watch the live feed instead (either on the touch screen or the live feed in the software).

Or another example, maybe you are a teacher in a STEM lab, and you want to monitor what the students are doing on your Muse 3D Autofocus Laser. You don’t want to hinder their creativity by hovering over them, so just sit back at your desk, pull up the live feed of the workspace on your computer, and keep watch from there. Make sure the students are aware of the safety precautions necessary, and have them pass the safety certification test first!

How does this help you or your business?

So with the 3D camera and Motorized Autofocus working together, the Muse desktop laser systems will increase your workflow efficiency by eliminating the hassle of manually focusing and making it much easier to place your designs accurately on your materials. Not only do these features speed up the process, but they make it much easier to use your laser. If you are a business owner, this will help your return on investment by allowing you to get more jobs completed in a shorter amount of time. And if you are just an enthusiast maker, this will help you be able to focus on creating your projects and won’t hinder your creativity with an extended process.

Full Spectrum Laser pushes the envelope with features like this, and will continue to innovate (It’s one of the benefits of having laser systems designed and manufactured in the same location). If you have further questions, we are here to help you out. Feel free to contact us at any time and we will be happy to assist you.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.