Thinking of buying an xTool D1, a different diode laser or a CO2 laser? No doubt there are a lot of different laser cutters and engravers out there, so it’s really easy to get confused by all of the options. Looking at the different price points makes it even more overwhelming. Lets face it, your pocket book is an important factor to consider when it comes time to invest in a laser machine, but there are a few important factors besides price that should also be considered.

Two of the most common types of lasers out there are CO2 laser machines (like Muse) and diode lasers (like xTool or FABOOL). These may have similar functions, but when you dig deeper into the specifics there are key differences that can affect overall productivity and efficiency. Doing adequate research ahead of time will be the best way to prepare yourself to make the right investment decision that will meet your specific needs of today and tomorrow.

What is a Diode Laser like XTool D1?

Diode lasers, also known as an injection laser diode, is a solid state semiconductor device similar to a typical light emitting diode (LED), but it can generate conditions suitable for lasing at the junction point between the positive and negative boundary. We have used diode lasers in our daily lives for quite some time, most notably in devices such as DVD or BluRay players, and even office laser printers.

In a tool such as the xTool D1 or the FABOOL Laser Mini, the diode laser has enough power to engrave and maybe even cut materials like wood and plastics. These lasers have the advantage of being in a small, portable form factor, while utilizing low current and low voltage.

These diode laser engravers typically emit blue light since it has the ability to produce a finer focal point compared to the other colors of diode lasers. That’s why you’ll notice a transparent yellow casing around the laser head on many of these units. The yellow cancels out the blue light, making them much safer to use.

What is a CO2 Laser like Muse?

CO2 lasers are one of the most useful, versatile types of lasers cutting and engraving machines that you can purchase today. The active laser medium is either a water or air cooled gas discharge that is mostly made up of carbon dioxide (CO2) hence the name. Nitrogen, Hydrogen, Xenon, and Helium may also be present, but the CO2 is the main medium that produces the laser emission.

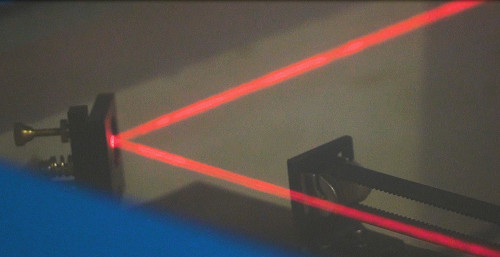

The CO2 lasers are larger than diode lasers, so the tube is usually fixed in a specific location in the machine and the beam is bounced via a series of mirrors on a gantry before it is finally focused using a lens just before it cuts or engraves the materials. Some CO2 lasers also use a galvanometer (AKA galvo) to direct the laser beam using motorized mirror mounts, but this isn’t as common as the gantry system.

The light that CO2 lasers produce is invisible on the far end of the infrared range of the light spectrum. So usually a red diode laser (similar to a laser pointer) is combined with the CO2 laser via beam combiner in the laser path. Most CO2 lasers range from around 40W up to 150W, though there are more powerful variants that are mostly used in the industrial sectors.

Time is Money

One of the most important factors to consider when thinking of buying an xTool D1 or a diode laser vs. a CO2 laser is the time that it takes the laser to complete a job. Regardless of whether or not this will be for a business, a hobby or you are an enthusiast that wants to take your hobby to the next level now or in the future, your time is always valuable.

From a layperson’s viewpoint, the sheer raw power that can be pushed into a CO2 laser allows them to cut through material much easier than a diode laser. So the optimal way to cut or engrave on material is to find the highest speed and lowest power setting possible. With this in mind, the speeds that the CO2 laser cutters and engravers will be able to complete the job will be much faster than what a diode laser can accomplish. Your time is one of your most valuable assets. A CO2 laser machine will help you spend less time waiting and more time getting more things done.

Size Matters

A CO2 laser with a glass tube can take up a bit of space. The glass tube itself will be a couple feet long, then you have to factor water cooling into the equation. So when all is said and done, and you have your CO2 laser set up and ready to go, it can take up most of your desktop. Still, being able to use a desktop space for a productivity machine like a high quality CO2 laser is attractive.

On the other hand, a typical diode laser source can fit in the palm of your hand. Because of their smaller size and low power, they can fit as a standard attachment for a CNC.

Safety First

CO2 Lasers can come in such a wide range of power that almost all of them will have the entire machine's work area enclosed for safety concerns. Unless there is a red diode paired with the CO2, the laser beam will be invisible to the human eye, so fail safes are in place to prevent contact with the laser beam. There is also a lot of electricity going through the laser tube, so this enclosure prevents the risk of electric shock.

While safety is still a priority when working with a diode laser, the concerns are far more minimal due to the lower power. The source is located at the head of the unit, meaning no beams are being reflected via a system of mirrors throughout the workspace. With the power requirement being much smaller, the risk of electric shock is minimal.

Ultimately the factors that make a CO2 laser a more capable, productive machine in terms of power and speed also require more safeguards. With that in mind, every laser manufacturer will take proper safety precautions to make sure the CO2 lasers that they are producing are safe to operate. The only way to risk your safety is to make unauthorized modifications or remove the fail safes such as the sensors that detect when the lid is open/closed.

Verdict

Both types of lasers can be very useful and will drastically help to increase your creative output, but the power, speed, and versatility of the CO2 laser machine makes them a better productivity and efficiency option. If you are thinking of buying an xtool D1 or other diode laser, CO2 lasers will likely be more expensive, and take up more space. However the return on investment for a CO2 laser machine is definitely worth the consideration for any business. Even if you are starting out using your laser as a hobby, the ability to start a business anytime in the future will be there when you have a high quality CO2 laser machine. Even the smallest of the CO2 laser cutters and engravers, such as the Muse Core, will outperform diode laser options such as xTool D1 or FABOOL. That means finishing a project faster and being able to complete more items with your laser, much quicker.

Still confused? We are here to help and can make sure you get the right laser to match your needs. Contact us at any time and a laser expert will get back to you as soon as possible.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.