Preventing Burning When Laser Cutting Wood

Due to the nature of CO2 laser cutters and engravers, completely eliminating burning when laser cutting is usually unavoidable. The CO2 laser will produce a stimulated emission of radiation through an active medium of discharged gas. So to put that into layperson terms, the laser beam produces a very intensely focused beam of light which essentially focuses heat on the material to burn or ablate it. When this process is applied to Wood, burning is unavoidable, but there are insights and tips that can help prevent high levels of burning and reduce it to a more desirable level.

There are a couple different ways that burning will occur when using your CO2 laser system to cut wood: Edge Burn and Flashback.

Preventing Burning When Laser Cutting Wood: Edge Burn

Edge burn is a natural occurrence when cutting certain materials with a laser cutter, such as wood. This is the darkened and sometimes charred surfaces that you will see along the edges of the cut. It is the result of the laser touching the material during the cut. This can give a piece beautiful contrast or it can create overly burnt edges.

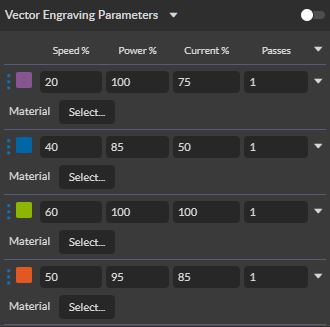

The amount of edge burn can vary depending on the settings that were used. If the power is set too high and the speed is set too low, the edges will come out black and charred. You’ll notice this when you handle the wood as the soot will rub off easily and leave soot marks all over your hands. If you get the settings correctly dialed in, your edges will appear as a rich amber color and you’ll have a minimal amount of soot rubbing off onto your hands as you handle it.

Make sure you always have extra material on hand so you can use the vector cut tests available to download here to dial in your laser settings to make sure you get your desired results. You may run into the issue where speed and power adjustments aren’t enough to reduce char on your vector cut edges. If this happens, try adjusting your vector current to dial in your cut even more.

Adjusting the current will adjust the speed at which the laser will fire as the head passes over the material, which can help reduce the amount of edge burn. So make sure you find the best combination of power and speed settings before you adjust the current settings to get the results you want. After you figure out the best combination of settings, make sure you log it by using a materials test log, ours can be downloaded here.

Please note that there is no single setting that can be given that will work for every sheet of wood you use in your CO2 laser cutter and engraver. Different types of wood will require different settings, and different lasers systems will use different settings as well. For example, if you use a sheet of birch in your 40W Muse Core laser cutter then take that sheet to your 90W Muse Titan laser cutter, the settings that will be used on the Muse Titan will be different than those used in the Muse Core. Also, the laser tube is a consumable component that will need to be replaced within the lifetime of your laser system. You may find the settings you have logged will need to be slightly tweaked to accommodate a fresh new laser tube that is firing at peak efficiency. Adjusting these settings over time is normal as well, since your laser tube will slowly be depleted as it is used.

Preventing Burning When Laser Cutting Wood: Flashback

The work bed and honeycomb that are used inside of your laser system are made of metal. Naturally, metal is a conductor of heat, so when the laser hits those metal components it will immediately heat up and create small burn marks that appear as small nicks, and sometimes even a smoky or cloudy mark.

The work bed and honeycomb that are used inside of your laser system are made of metal. Naturally, metal is a conductor of heat, so when the laser hits those metal components it will immediately heat up and create small burn marks that appear as small nicks, and sometimes even a smoky or cloudy mark.

If you compare those flashback marks, you’ll see that they match up with the honeycomb tray that is being used inside the laser system’s workspace to elevate your material to give a cushion of air beneath to allow the laser beam and air assist to pass all the way through. If you remove the honeycomb and rest your sheet of wood directly on the metal floor for laser cutting, you’ll get even more dramatic flashback results and increase your chance of fire.

Knife edge tables are one way to prevent flashback, but they are typically only available on the more industrial and high production laser systems like the P-Series. But on the Muse Series, dialing in the settings will be the best way to combat flashback. Trial and error is going to be your best way to learn how to reduce the flashback on the different types of wood that you will be cutting. So always have spare material on hand for testing.

Preventing Burning When Laser Cutting Wood: Finishing

You may not be able to completely eliminate flashback or edge burning when cutting wood with your CO2 laser cutter, but you can use a variety of finishing methods to fix the results. Before you use these methods, it is recommended to still make sure your settings are optimal in order to reduce the amount of finishing time to be as minimal as possible.

These finishing methods include, but are not limited to the following:

- Sanding: You can sand down the edges to reduce the amount of edge burn, or even sand the surface to get rid of all the edge burning.

- Painting: Using paint to cover the burned edges and flashback is one of the easiest ways to fix the issue. Use your best judgment and experiment with different paints to get the best results (e.g. spray paint may not absorb evenly into the wood, and you will get different results with brushed on acrylic paints)

- Staining: Wood stain may not completely cover the burn marks, but you can use it in combination with sanding to get great results. If you use an oil based stain, do not put that wood back into the laser after it has been stained, as it will be even more flammable.

- Masking: This one is more of a material preparation than a finishing option. You can lay down a single layer of masking tape or contact paper to reduce the amount of flashback that happens, though you may need to slow your speed down or increase the power slightly to accommodate the extra layer of different material that is now covering the wood.

Wood is probably the most readily available material that you can purchase for use in your co2 laser cutter. Use these steps for preventing burning when laser cutting to get the best results, and don’t forget to experiment and try new ideas you may discover to reduce edge burn and flashback… and as always, wood is flammable, so stay safe, have a fire extinguisher within reach, and never leave your laser unattended while it is running.

Full Spectrum Laser is a leader in easy to use, highly versatile laser cutting and laser engraving machines. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.