Laser for Cutting: Tips, Tricks, and Topics

Whether you are using your laser for cutting, engraving, or both, there are many things that you can do to increase your workflow which in turn will give you better results and potentially increase your return on investment. These things can vary from simple material preparation to laser cutter service and maintenance. Even understanding the basics of how your laser and its components function together will help you get the most out of your laser system. In this article, we will discuss a few tips, tricks, and topics that will help you use your laser more productively.

Laser for Cutting Tip: Focusing Your Laser on Uneven Surfaces

When it comes to using a laser for cutting, not all projects are made on perfect, flat pieces of material. Some applications might have uneven surfaces, such as this ukulele example that we will reference below. When a design comes out of focus range, the output will become blurred, distorted and/or faded. If this is the case, it is easy to be confused on how to focus the laser for the best output for the uneven surface.

To help correct this, with a 2.0” focal lens, the laser can be out of focus up to 1/8 of an inch either way and still achieve a good raster engraving.

Split the Difference: For the best results you will have to split the difference between the highest point and the lowest point of your piece. Using a standard 2.0” focus lens, you have a depth of field (DOF) of a 1/4 inch to achieve your raster on a uneven surface. This means you have 1/8th of an inch below and 1/8th of an inch above the focus point. Note that focus lenses can vary in length and each will have a different depth of effective focus.

.png)

Breaking up uneven surfaces: Some designs will have to be broken up into separate files. If a given project has two different heights that are outside of 1/8 of an inch of difference, then you will have to break up your design into multiple files and focus and cut each separately.

Laser for Cutting Trick: Designing Notches for 3D Objects

Notching is a technique that makes 3-dimensional laser cutter projects easy to design, create and assemble. Notches allow us to add stability as well as a method to hold our individual pieces together. By using different designs of notches, we can also create projects that vary in both design and function.

Know your material height: When you’re designing notches in your favorite software, you need to consider the thickness or height of your material, as this will indicate the height of your notch. When creating notches, an accurate measurement of the material height is crucial. It is recommended to use a ruler that has notches less than 1/8 inch, or use calipers to get even more precise measurements.

Spacing and Fitting: Because the laser cuts such a precise line, you don’t need to plan for spacing to align your joints in assembly. You can simply share vector lines with a single vector cut This will save time and material and the piece will slide together perfectly.

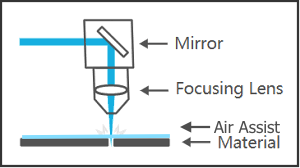

Laser for Cutting Topic: Understanding Air Assist

The air assist feature comes from an air compressor which is attached to the laser system and feeds a stream of air to the laser head. This air is blown over the material the entire time that your laser is being used to cut or engrave. As demonstrated in the diagram, the constant flow of air creates a cooling barrier between the laser beam and your material to keep the laser at a safe operating temperature. Without the air assist in some usage scenarios, it is possible that a laser beam and material could heat up to the point that it is a hazard (always keep a functional fire extinguisher with your laser system). While one of the main functions of the air assist feature for a laser cutter is safety and cooling, there are also cutting and engraving benefits as well. Most higher performance, high quality CO2 laser cutters like the Muse Titan will feature air assist.

Keeping the Laser Cool: The air assist works in conjunction with a water cooling system. Water will flow through an enclosed pathway in the laser tube and keep the glass from shattering..

Help the cut, reduce the char: Besides being a safety feature, integration of a strong air assist is helpful in reducing warping or charring of your material from the high power of a laser. We have a more in depth explanation of how to avoid charring in our comparison of power and current, but the key theme is to use the lowest power setting required to get the job done. Sometimes a higher power is needed to achieve a clean cut, and the air assist feature can help ensure that the cut is not obscured by a deep charred edge or burn marks.

Take these tips, tricks, and topics and apply them to your repertoire of laser cutting and engraving knowledge. The more you know, the further your laser cutter and engraver will take you.

Full Spectrum Laser is a leader in easy to use, highly versatile laser cutting and laser engraving machines. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.