Wood is one of the most commonly applied materials that are used with laser cutters and engravers, and there are many reasons for that. Compared to other materials, it has relatively inexpensive options and looks fantastic when used with both desktop laser cutters and industrial laser cutters. Best of all, it is very easy to find at your local hardware store where you can have it cut down to the size you need for laser engraving on wood.

Wood Properties

Origins:

Wood is a natural, and readily available material derived from trees.

Grain:

Different densities and directions of grain can produce varied results.

Growth Rings & Knots:

When laser engraving on wood, CO2 lasers will react differently when they try to cut or engrave knots and other irregularities within the same piece of material. To get the best results for both cutting and engraving, try to find wood that has fewer knots, growth rings, and other blemishes.

Moisture Content:

Dry wood is affected differently by laser cutting and engraving than moist (or green) wood.

Oil and Resin Content:

Wood with high resin and oil content will tend to edge burn more strikingly and have a higher potential to produce flashback onto the underside of the material.

Wood Types

- Natural Wood (unprocessed with chemicals)

- Softwood

- Birch (easy to find, readily available)

- Pine (great choice for laser cutting)

- Cedar (soft, straight grain, pleasant smell)

- Fur (inexpensive but dull look. Best when painted)

- Redwood (reddish tint, resistant to moisture)

- Hardwood

- Ash (hard to find, finishes well)

- Birch (readily available)

- Cherry (popular for furniture)

- Mahogany (works great with lasers, hard to find)

- Oak (beautiful grain, easy to work with)

- Walnut (works well with laser, expensive and rare)

- Cork (naturally buoyant, elastic and fire resistant)

- Balsa (very lightweight, inexpensive, great for laser cutting)

- Bamboo (technically not wood, but widely used in cutting boards which are great for engraving but difficult to cut with good results)

Woods Not Recommended For Laser Engraving or Cutting.

Fiberboard:

Fiberboard is made of glued wood fibers, which can inhibit the laser and create poor results as well as noxious fumes.

Exotic Hardwoods:

Extremely dense hardwood can be difficult to cut and produce inconsistent results when engraving. Hardwood maple is included here.

Mexican Elder, Oleander:

The fumes from cutting and engraving creates noxious fumes.

For other materials you should avoid with your laser cutter, check out the Full Spectrum Laser Community Forum on Facebook. Someone has likely already tried the type of wood you would inquire about, as well as give you tips and tricks to give you the best results with that type of wood.

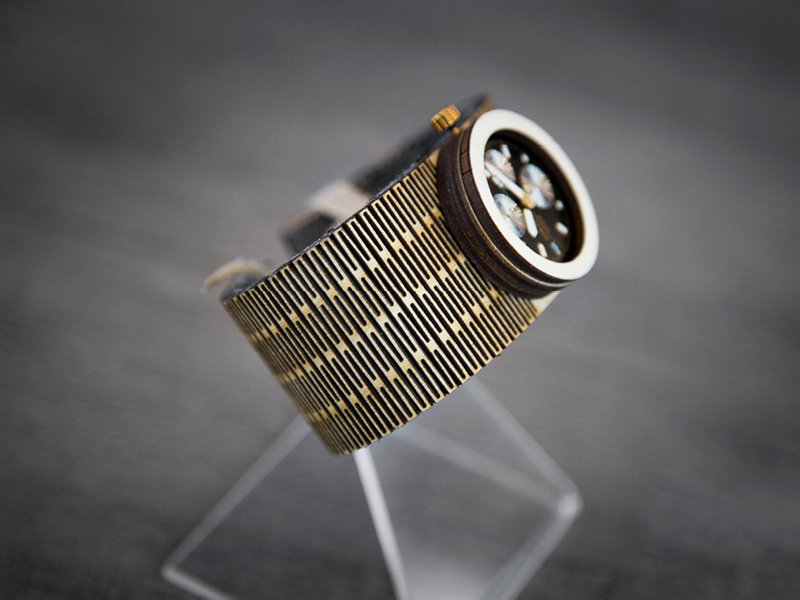

Laser Engraving on Wood: Applications

General Approach:

Start with quality wood that is flat and with minimal knots and imperfections. If you are cutting or engraving plywood, try to find flat sheets that are not warped. You may also get varied results with sheets of ply wood due to the density of the different layers as well as the glue used to hold those layers together.

Edge Burn:

Edge burn is a natural occurrence when the laser vaporizes the wood, leaving a darkening on the edges. Although edge burn cannot be avoided entirely, drier woods with less resin and oil will produce a lesser edge burn effect.

Thickness:

Generally, a 40W to 45W CO2 laser like the Muse Core or 3D autofocus can cut up to ¼ “ thick wood, while a laser such as the P-Series PS24 or Muse Titan with a 90W Tube can cut up to ½” thick wood. You can use multiple passes to cut through sheets that are thicker than that, but your results may vary, and you may see an excess of charring. It is recommended to find the best settings on your laser wood cutting machine to produce a clean cut on a single pass.

Density:

Wood comes in a wide scale of hardness, which will affect your power and speed settings.

Wood Finishing Tips

Cleaning:

After vector cutting there will be a sooty residue on the edges. Use a rag to gently rub off any excess soot. For laser engraving on wood, a rag may rub out desired contrast, so wash with a gentle flow of room temperature water and let air dry.

Preserving:

A good finish will preserve and protect your piece. Be aware of safety precautions when using finishing chemicals.

Enhancing:

Like any wood product, you can stain to enhance wood’s natural beauty. You can also use paint to add color or cover up imperfections in the wood, such as knots. Just make sure you use your stain after you are done laser engraving or laser cutting wood, as most stains are oil based and can be flammable.

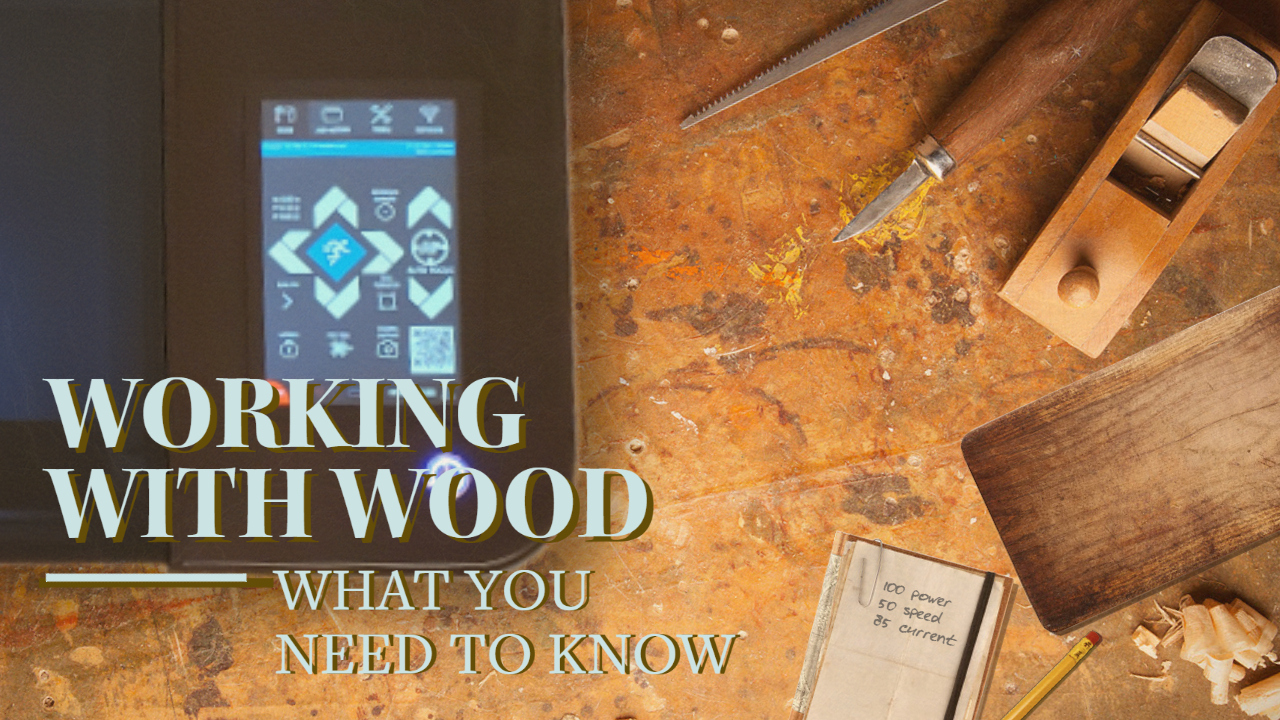

Laser Engraving on Wood: Settings

Your power, speed and other laser settings are going to vary depending on things such as thickness and the type of wood you are cutting or engraving. Even the wattage of your laser and the local environment can affect settings. Because of this, instead of giving arbitrary settings, we recommend doing a materials test on a piece of scrap wood or in an unused corner of your project material. You can download our Material Test and log book at our website.

Wrap up

Due to it's versatility and availability, you'll likely spend a lot of your time working with many different types of wood with CO2 laser cutters and engravers. This article should give you an idea of what to do, and what not to do, when laser engraving on wood. Your safety is very important, so make sure you are always taking safety precautions, never leave the laser unattended when in use, and have a fire extinguisher handy.

But the best way to learn what works best when laser engraving on wood is to dive in and don't be afraid to make mistakes. Always have extra material on hand, and don't be scared to experiment. Trial and error is going to be your best path on your journey to becoming a laser expert.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.