There are many times when using a CO2 laser cutter and engraver where certain items or materials just don’t fit inside the machine's workspace. These items or materials might be too long, too wide, or too tall to fit inside the enclosed workspace. This can be very frustrating, especially when you start to understand the capabilities of a CO2 laser engraver. What if there was a way that you could still work with these larger materials? This article discusses a best laser engraver feature: removable floor.

CO2 Laser Capabilities

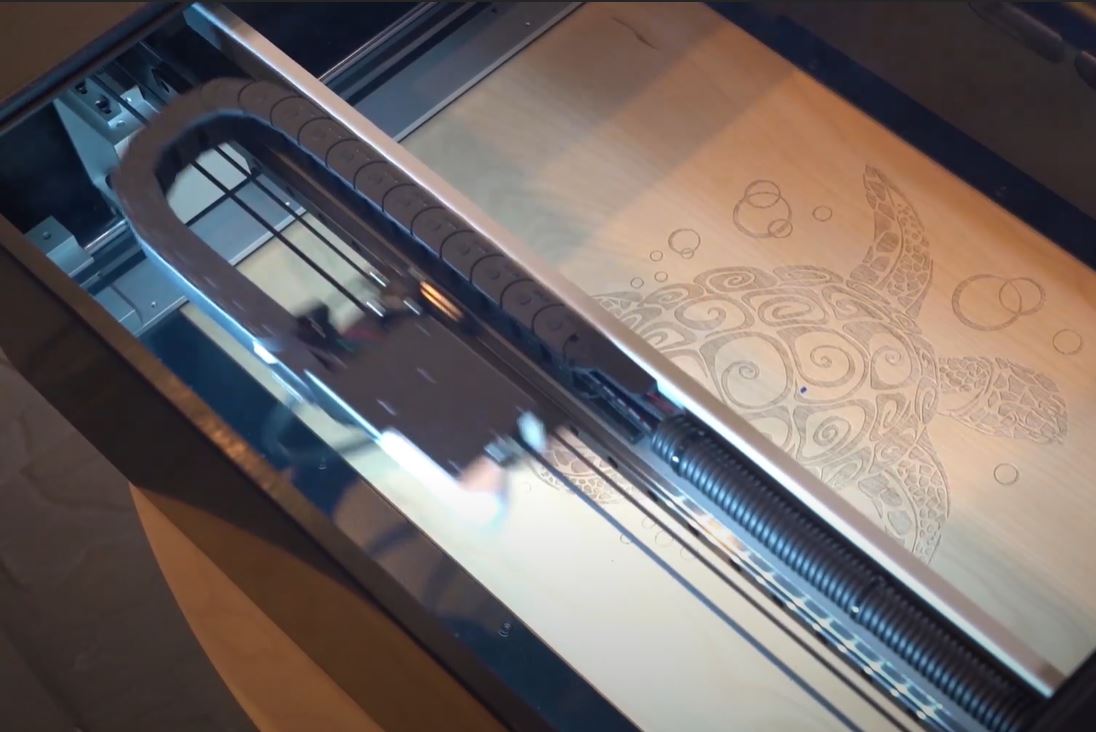

CO2 laser systems are capable of working with a wide array of materials. The laser beam that is generated from the CO2 laser tube emits invisible light in the infrared range at 10,600nm, (or 10.6μm). That may seem like a large number, but to put that in perspective, the average human hair is at least five times wider. This wavelength is optimal for cutting and engraving organic materials such as wood and leather.

The Larger Sized Material Challenge

If you’ve ever been to a lumber yard, you’ll notice that most of the planks and sheets of wood are large. The available options are usually at least around four feet in length, with many of the options being even larger. The average desktop laser cutter and engraver has a workspace that is around 20 inches by 12 inches.

Now you’re probably thinking that it’s really easy to just get a saw and cut the material down, and most lumber yards offer a service where they will cut the material for you. But take a look at all the wooden items around you as you sit in either your home or office. You’ll quickly realize that most items that you see which are made of wood are usually large sized objects.

The desk you are sitting at is probably made of wood.

The door that you walked through is probably made of wood.

And there’s even a good chance that the floor beneath you is made of wood.

When you begin to regularly use a CO2 laser engraver, you’ll begin to get ideas and start to see objects that would look amazing with a custom engraving. At first you’ll see all the little things that will fit inside your machine, but then you’ll start to see larger objects like wood dining tables or wooden doors that would look really good with a custom engraving. Even if you have a larger industrial laser, there is a very good chance that these objects will not fit inside the workspace of your system. They will either be too long or they will be too tall to fit. Is there a solution for this challenge?

Best Laser Engraver Feature: Removable Floor

This is what sets the Muse Series desktop laser engraver systems apart from the rest of the competition. The engineers at Full Spectrum Laser try to think outside of the box, or in this case, outside of the laser, when designing and engineering these systems. The removable floor featured in the Muse Core and 3D Autofocus systems is an exclusive patent that is aimed at solving problems like these. Even the larger Muse Titan laser engraver system has the same removable floor feature as its smaller counterparts. While the Titan may have a larger 48 inch by 24 inch workspace and built in passthrough system, there will be instances where this still may not be enough, and the removable floor expands its capabilities of cutting and engraving beyond those dimensions.

Removable Floor Usage Examples

When you remove the floor of these systems, you can place it directly on your larger materials in order to engrave on them. You can even prop up the laser and put larger objects under them to engrave that otherwise may not fit inside the workspace of the laser because of their height. A few examples are listed and shown below.

Engrave on a table: Remove the floor from the bottom of the Muse and place it directly on the wooden table for engraving.

Engrave a door: Take the door off its hinges and lay it horizontal. Place the Muse with its floor removed directly on the door.

Engrave wooden floors: Clean the floor and engrave directly on wooden floors. You may even be able to engrave on a ceramic tile floor.

Engrave large oddly-shaped objects: Larger objects with unusually shaped or with curved surfaces that don't fit into the enclosed work area such as wine barrels and wooden storage chests can be engraved. Since they are not stable enough, or large enough to rest the Muse directly on them, you can prop the muse up so you can place the item under the machine to engrave. If you do this, make sure the surfaces that you rest the muse on are stable and capable of holding the weight of the Muse.

With the floor removed from these laser systems, a rotary will be able to fit and function with the system. The Muse Core and 3D Autofocus have a riser that they can be rested on to expand the Z-height of the workspace making sure the workspace is still safely enclosed. Keep an eye out for future articles discussing more benefits of using the rotary with these systems.

These are just a few ideas to get you in the proper creative mindset. If you have a larger object that you want to engrave upon, with the best laser engraver feature: removable floor, the Muse series CO2 lasers can get that taken care of for you. Just remember that safety should always be your first priority. When you remove the floor of the laser, you are exposing the beam. Make sure there are no pets or small children nearby that can reach or run under the laser beam, and make sure you take all of the necessary safety precautions.

With The Removable Floor You are in Control

With the Muse Series desktop lasers, you are truly in control of what you can create. These best laser engraver features, such as the removable floor, are there to help expand the possibilities of your machine giving you endless creative possibilities.

Full Spectrum Laser is a leader in laser cutting and laser engraving systems. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.