Beyond the Blast

Why UV Laser Engraving Is the Best Alternative to Traditional Sandblasting for Glass

When it comes to surface treatment and engraving, sandblasting has long been relied on for cleaning, etching, and finishing materials. But when it comes to engraving glass, sandblasting and even acid etching can be time-consuming, imprecise, and potentially damaging.

Fortunately, modern alternatives—especially UV laser engraving—offer not only superior results but also faster processing times, making them the clear winner in today’s fast-paced production environments.

This guide explores alternatives to sandblasting, compares their performance, and explains why UV laser engraving is the best, fastest, and most precise option for glass engraving today.

Why Move Beyond Traditional Sandblasting?

Before we evaluate the alternatives, it's important to understand the limitations of sandblasting—especially when used on glass:

Key Drawbacks of Sandblasting:

- Time-Intensive: Preparing the workspace, masking areas, setting up containment, and cleaning up abrasive media can significantly increase turnaround time.

- Damage Risk: Abrasive media can easily chip or crack glass if not handled with extreme care.

- Inconsistent Detailing: Achieving fine or intricate patterns is slow and often unreliable.

- Dust & Cleanup: Post-process cleanup is laborious and requires extra time and safety precautions.

Alternative #1: Acid Etching

Acid etching chemically reacts with surfaces to create a frosted appearance on glass. It’s a popular alternative to sandblasting, but it’s not without time and safety trade-offs.

Time Challenges:

- Slow Reaction Time: Etching glass chemically can take several minutes per piece—and that doesn’t include prep and rinse cycles.

- Manual Handling: Stenciling, dipping, timing, rinsing, and drying must be done carefully and often manually, leading to longer production times.

- Batch Constraints: Acid etching isn’t well-suited for high-speed or high-volume production environments.

The Laser Leap: Why Laser Engraving is Faster and Better

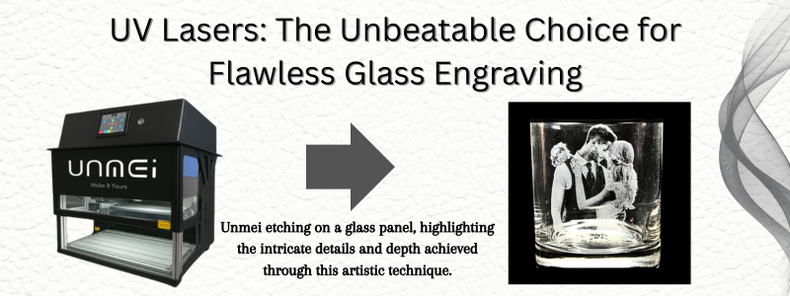

Laser surface treatment, and in particular UV laser engraving, revolutionizes how glass is marked—delivering clean, high-detail results in a fraction of the time it takes with other methods.

Time Advantages of Laser Engraving:

- No Prep Work: No need for masking, abrasive material, or chemical handling.

- Instant Results: Designs can be engraved onto glass in seconds—not minutes.

- Seamless Automation: Easily integrated into automated production lines, minimizing operator intervention.

- On-Demand Flexibility: Switch from one design to another instantly with digital controls—no physical templates or stencils needed.

Why UV Lasers Are the Best Choice for Engraving Glass

Among laser types, UV lasers (ultraviolet lasers) are specifically suited for glass because of their short wavelength (~355 nm), which is strongly absorbed by transparent materials.

Advantages of UV Laser Engraving on Glass:

- Fast and Efficient: Processes glass surfaces in seconds with no cleanup required.

- Minimal Thermal Stress: Cold marking reduces the risk of cracking and deformation.

- High-Resolution Detail: Ideal for logos, barcodes, decorative designs, and text—even on curved or irregular surfaces.

- No Consumables or Mess: Unlike sandblasting or acid etching, there’s nothing to dispose of post-process.

- Scalable: Perfect for both one-off items and high-volume runs.

How Other Lasers Compare (and Fall Short on Glass)

- CO₂ Lasers: Can process glass but are prone to overheating and cracking due to higher wavelengths.

- Fiber Lasers: Great for metals but largely ineffective on transparent surfaces like glass.

- Nd:YAG Lasers: Versatile but don’t absorb well on clear materials.

- Ultrafast Lasers: Extremely precise but expensive and often overkill for standard engraving.

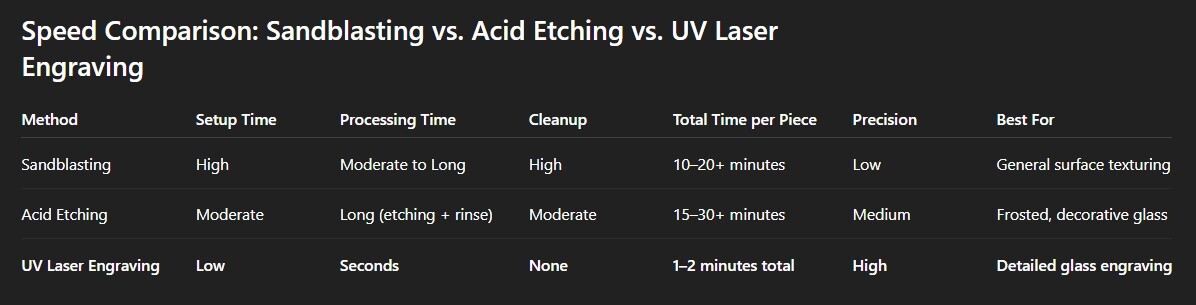

Speed Comparison: Sandblasting vs. Acid Etching vs. UV Laser Engraving

Final Verdict: UV Laser Engraving Is the Fastest, Cleanest, and Most Precise Way to Engrave Glass

In today's world, speed and precision matter. While sandblasting and acid etching are traditional methods, they’re slow, labor-intensive, and risky for glass. UV laser engraving not only delivers unmatched quality but does so in a fraction of the time—without chemicals, dust, or waste.

Whether you're customizing glassware, engraving awards, or creating intricate artistic designs, UV laser systems are the best choice. They offer professional, repeatable results while slashing processing time and overhead.

Optimized for Search: Key Takeaways

- UV laser engraving is the best method for glass in terms of speed, quality, and safety.

- Laser engraving cuts production time from 20+ minutes down to 1–2 minutes per piece.

- Unlike sandblasting and acid etching, UV lasers require no cleanup and work perfectly on fragile glass.

- For businesses looking to scale production and reduce turnaround times, UV laser engraving is the clear solution.

Ready to upgrade your glass engraving process? Embrace the speed, safety, and precision of UV laser technology—and leave traditional methods in the dust.