Printed Circuit Board, also known as PCBs are boards made of non-conductive material that have conductive material added to ensure the formation of a circuit. There are various different types of circuit boards that are used for different jobs, the production of which takes time and causes a lot of waste materials. However, the introduction of laser engravers has revolutionized the industry by making a fast, resource efficient way to engrave and cut PCBs. In this article we will explore how a MOPA laser machine from Full Spectrum Laser can be utilized for cutting and engraving PCBs and highlight their effectiveness over traditional methods.

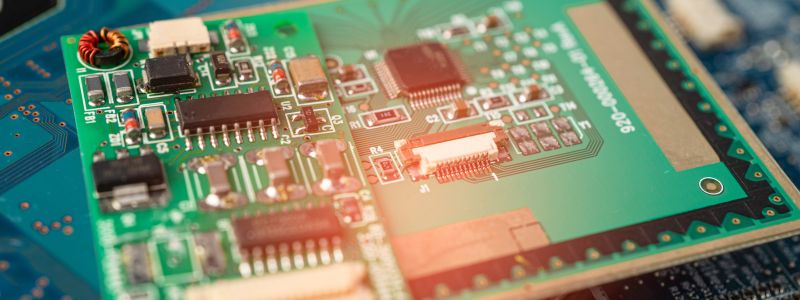

How are PCBs cut?

Traditionally, cutting PCBs involves the use of milling or routing equipment and in some cases box cutters. Engraving on PCBs normally involves chemical etching on areas that will not come in contract with the circuit components. On the other hand, a MOPA laser engraver can perform highly detailed and intricate cuts with ease. Our laser machines can easily have their output settings adjusted using Retina Engrave v3, ensuring stellar engravings without damaging or distorting the board.

Cost-Effective

The need for complex tooling requires a large start up cost and will require the hiring of skilled workers to reduce the amount of material not used. A laser engraver will also have a large start up cost, however a laser machine can be used with minimal training. Additionally the effectiveness of the machine will ensure that more material is usable, cutting down on material costs overall.

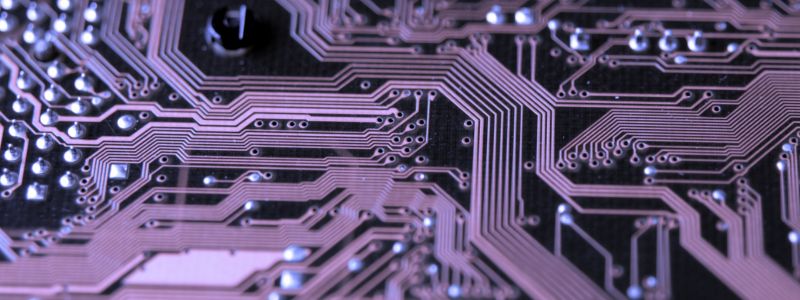

MOPA VS Traditional

MOPA laser machines offer numerous advantages over traditional methods. The precision offered helps reduce the time and labor needed to prepare the circuit boards. Unlike the old methods that require skilled workers and specialized equipment, the MOPA only requires a laptop and internet connection to function. Additionally, our laser machines are able to engrave a variety of different materials, including aluminum, plastic, and other materials, making the machine suitable for a number of different applications.

Laser engravers have brought about a large shift in PCB production. Their precision, versatility, and cost-effectiveness make them the preferred choice, replacing traditional methods. Buy a Full Spectrum Laser machine and start revolutionizing your workplace.