Laser Classes: What you need to know

If you are initially researching lasers, and are interested in a new laser cutter and engraver, laser classes will be a recurring specification that you will notice listed in most laser cutter product spec sheets. Laser systems are broken down into a series of classifications for safety reasons. The classes determine the potential extent of damage and injury that a specific system can inflict on humans’ eyes and skin. We will discuss these classifications further in this article so you can understand what laser classes will work best for you and your needs.

Brief History and Overview of Lasers

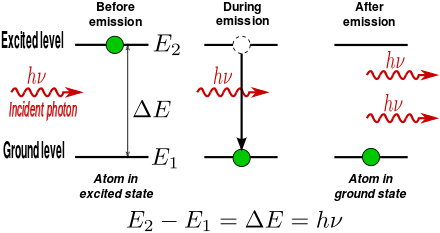

Over one hundred years ago, in a 1917 paper titled “The Quantum Theory of Radiation,” Einstein discussed a quantum phenomenon called stimulated emission. In this phenomenon, Einstein predicted that the electrons could be forced into unstable orbits inside of atoms, which is a method that could be used for energy to be released from atoms. This only references the classical emission process to create a laser beam. There are other methods for more advanced research and military lasers that are free electron lasers where atomic energy levels are not involved.

Image Source: Wikipedia

Thanks to the invention of lasers, a multi-billion dollar industry has sprung into existence. Lasers are used in multiple industries, ranging from healthcare, consumer electronics, manufacturing, and more. Due to modern innovations, the laser has evolved to the point where it can be added as a safe cutting and engraving tool for small and medium business owners and even home craft enthusiasts and makers. Although many laser cutting and engraving machines with enclosures are quite safe, lasers themselves can be very harmful to humans and animals, causing burns on the skin as well as significant eye damage. Since lasers are embedded in countless devices all over the world, a system of classifying them was necessary in order to regulate safety. The information in this article is taken from multiple sources, all of which cite IEC 60825-1:2007.

Laser Classes: What are they?

Lasers are considered a type of radiation, and safety is a legitimate concern that requires regulation - thus the introduction of laser classes. Different types of lasers and how they are built into their systems reference a laser class to determine safety. The laser class is determined by the safety of the design and functionality of the given laser system or machine. A laser that is moderate to high powered can be potentially harmful because it can burn the retina and skin. The power and wavelength of the laser, as well as how it is enclosed within its system, will determine the laser class that is given. The current, revised system is specified by the IEC 60825-1 standard and is the system that will be detailed below:

Lass Class: 1

As long as the laser is being used under the conditions of normal use, this laser class is inherently safe. The maximum permissible exposure cannot be exceeded when viewing with the naked eye, or with the aid of magnifying optics (such as microscopes or telescopes). These are the types of lasers that we typically use on a day to day basis. Things such as laser printers, CD players fall into this category, as well as industrial and analytical equipment like geological survey equipment and laboratory equipment.

As long as the laser is being used under the conditions of normal use, this laser class is inherently safe. The maximum permissible exposure cannot be exceeded when viewing with the naked eye, or with the aid of magnifying optics (such as microscopes or telescopes). These are the types of lasers that we typically use on a day to day basis. Things such as laser printers, CD players fall into this category, as well as industrial and analytical equipment like geological survey equipment and laboratory equipment.

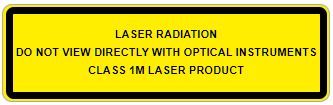

Laser Class: 1M

These lasers have a larger diameter beam than lasers that have the laser class 1 designation. But, if it has the potential to cause burns to the human eye if passed through something like a telescope or magnifying glass, then the laser class will be changed to 1M. Basically, when a laser has a 1M laser class, this means that it has the potential to become a higher laser class when the beam is narrowed by a magnifying optic.

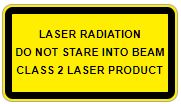

Laser Class: 2

Laser Class: 2

This laser class is similar to the 1M, but is reliant on the human blink reflex, kind of like the glare aversion response to bright lights. If the laser beam is this laser class, then it won’t cause harm as long as the exposure is less than a quarter of a second. If you intentionally suppress your blink reflex (ie: stare), you will likely cause eye injury. Some examples include some of the higher powered laser pointers, and other devices such as laser measurement tools.

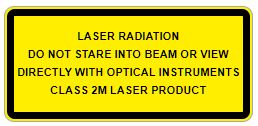

Laser Class: 2M

Laser Class: 2M

Just like with those lasers categorized in the laser class 1M, there is also a laser class 2M. Lasers that have the laser class of 2M have a beam with a larger diameter, but are still safe because of the human blink reflex as long as they aren’t viewed through any optics that can narrow the beam. Though, if the beam does get narrowed through optics, it will become a different laser class.

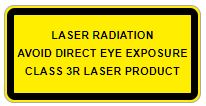

Laser Class: 3R

Laser Class: 3R

These are lasers that are safe with minimal safety concerns when handled carefully and as long as the beam exposure is restricted.

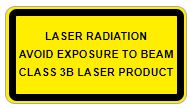

Laser Class: 3B

When the eye is exposed directly, there will be damage so protective eyewear is typically required when direct viewing might occur. These must be equipped with a key switch and safety interlock. For example, CD and DVD writers use this class of laser, but since it is safely enclosed and light cannot escape the unit, they are classified as laser class 1.

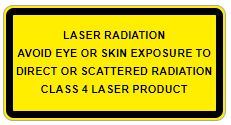

Laser Class: 4

This is the highest laser class and consists of all lasers that exceed laser class 3B. These lasers will burn the skin and can cause permanent eye damage when they come in direct contact with the beam. The damages may also occur with indirect reflections of the beam, even if the surface does not appear to be reflective. Many lasers that are used in the Medical and Military fields are designated as laser class 4. Also, industrial lasers can be designated as laser class 4 if they are not enclosed and the beam is not contained.

Laser Class: Laser Cutters and Engravers

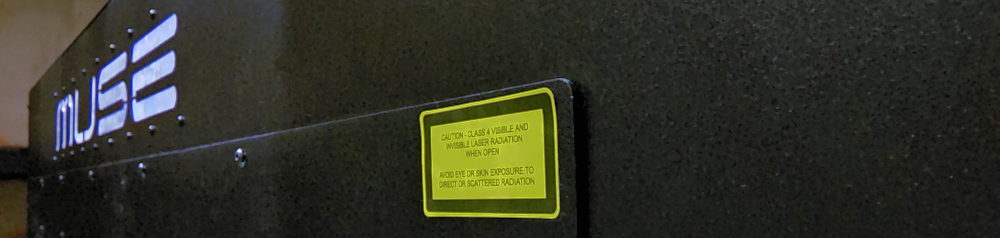

So how do laser cutters and engravers fit into this laser class structure? CO2 lasers can function within any of these classes depending on a wide variety of variables. The Muse Series and P-Series CO2 laser output is fully contained in a Class 1 enclosure during normal operation and no special precautions are necessary to operate the high power laser safely. However, the output beam of the alignment laser (visible red diode laser) is accessible to the operator during normal operation, giving the total system an overall rating of Class 3R. Class 3R lasers have minimal safety concerns when used properly and handled with care.

Regardless of which laser cutter and engraver you own and use, you should always take proper safety precautions to make sure you do not risk any harm to yourself and others that may be nearby. Never make any unsanctioned modifications to your system, and always take caution when operating these systems. There are safety interlocks in place, such as the lid sensor, which prevent the laser from firing when open. Do not modify these sensors at any time, and always monitor the sensor status which is displayed on either your 7 inch touch screen or on the bottom bar in the RetinaEngrave v3 software when you load it on your computer.

Full Spectrum Laser is a leader in easy to use, highly versatile laser cutting and laser engraving machines. Our systems range in size from desktop units and high-volume machines through industrial-grade production equipment. Our machines are running all over the world: from grade schools to National Labs, garage startups and many Fortune 500 companies. Contact us today to learn more.