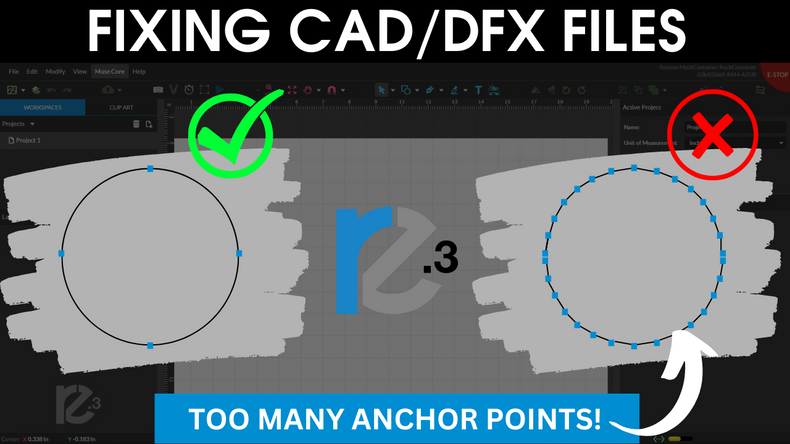

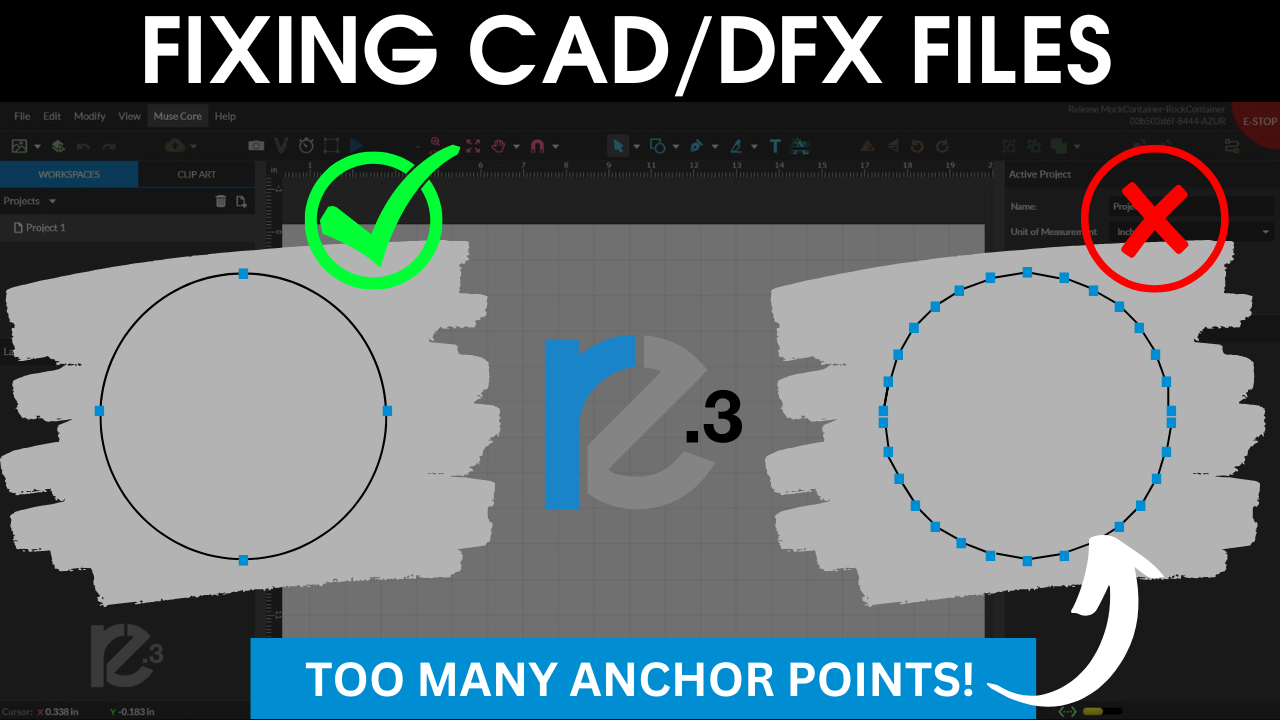

Cutting files for lasers are made of vectors. Vectors are made of anchor points, line segments, and arcs. Some programs prefer to make arcs in many small straight line segments. The issue with many small line segments and anchor points is that a laser stops at each point rather than following a clean point free path. The more points a vector has the more the laser stops slowing its travel causing issues with the output of a laser project. To prevent this in most design programs you simply reduce the amount of points in a vector, but some files from CAD programs or exported DFX's default to this many point based arc. To make your laser projects come out the best they can please follow the steps below when working with CAD/DFX files and or programs.

FSL receives many DXF files which are broken and don't cut well but here is how to fix them:

1) ensure there are no overlaps. We've seen files where there weren't lines but overlapping bezier curves or mini rectangles. Autocad has a feature OVERKILL that will remove all overlapping lines. Always run this first.

2) Use Autocad JOIN command to join curves. Sometimes this doesn't work then do step 3.

3) Use Autocad PEDIT command to join disjoint line segments into a single polygon. You may need to do this a few times. Select all the broken line segments and use the JOIN and CLOSE subcommands of PEDIT to close the curve completely.

4) Once in a single polyline, RE3 will directly import DXF files.

Summary: If they are broken, they will still cut but the problem is they will not be optimize and you will have a lot of random jumping around. Autocad is the only program we found with the function OVERKILL. Other editors can be used but you'll probably have to edit the nodes and other more time consuming tasks.

We recommend printing to a PDF file which is native format to RE3 or using something like a SVG file but DXF files are fine particularly if they're in groups of full polylines.

To test and see if your files export from your design software of choice properly you can simply open them in our online laser control software RE3.