CO2 lasers, which utilize a gas mixture of carbon dioxide, nitrogen, and helium to produce a laser beam, are incredibly versatile tools when it comes to working with wood. They offer precise and controlled material removal, making them popular choices for various material applications. However, like any technology, they also have limitations. Here's an overview of what a CO2 laser can and can't do with different materials:

What a CO2 Laser Can Do with Wood:

- Precision Cutting: CO2 lasers excel at precise wood cutting. They can cut intricate patterns and shapes in wood with accuracy measured in millimeters. This precision is valuable for creating detailed inlays, intricate wooden jigsaw puzzles, or precisely shaped components for woodworking projects.

- Engraving and Etching: CO2 lasers are adept at engraving or etching designs, text, and images onto wood surfaces. This is commonly used for adding decorative elements to wooden products, personalizing items, or creating intricate wooden art pieces.

- Scoring and Marking:These lasers can also be used for scoring and marking wood. Scoring involves making shallow cuts, often used for creating fold lines in wooden packaging or precise measurement lines. Marking is useful for labeling and identifying wood pieces.

- Customization: CO2 lasers provide a high level of customization. Woodworkers can design their own patterns, logos, or decorative elements and easily transfer them onto wood surfaces. This is particularly valuable for creating unique and personalized wood products.

What a CO2 Laser Can't Do with Wood:

- Thick Material Cutting: While CO2 lasers are excellent for precision cutting, they have limitations when it comes to cutting thick wood. The depth of the cut is limited, typically up to a few millimeters. Thick wooden pieces are better suited for other cutting methods like sawing or milling.

- Large-Scale Cutting: CO2 lasers are more suited for smaller to medium-sized woodworking projects. Large-scale cuts, like those needed for constructing furniture or large wooden structures, may not be efficiently achieved with these lasers.

- Non-Flat Surfaces: CO2 lasers work best on flat or slightly curved wood surfaces. Highly irregular or non-flat surfaces can be challenging to process accurately, as the focus of the laser beam may vary across the surface.

- Certain Wood Types: While CO2 lasers can work with a wide range of wood types, some dense or resinous woods may not cut or engrave as cleanly. The laser's effectiveness can be influenced by the wood's hardness, density, and moisture content.

CO2 lasers are valuable tools in the woodworking arsenal for precise cutting, engraving, and customization of wood materials. However, they do have limitations, particularly when it comes to thickness and scale. Understanding the capabilities and constraints of CO2 lasers is essential for woodworkers to make the most of these versatile machines in their projects.

What a CO2 Laser Can Do with Plastic:

- Precision Cutting: CO2 lasers are exceptional at precise plastic cutting. They can cut intricate shapes, patterns, and even intricate designs into plastic materials. This precision is valuable for applications such as creating custom plastic parts or fabricating intricate plastic prototypes.

- Engraving and Marking: CO2 lasers can engrave or mark plastic surfaces with precision. This is widely used for adding branding, serial numbers, or decorative elements to plastic products or components. The laser can produce fine details and crisp lines on plastic.

- Scoring and Creasing: CO2 lasers can score or crease plastic surfaces, allowing for easy bending and folding. This is particularly useful for creating plastic packaging or display materials with precisely defined fold lines.

- Customization: CO2 lasers offer a high degree of customization. Plastic items, from promotional products to signage, can be personalized with unique designs, logos, or text using these lasers.

What a CO2 Laser Can't Do with Plastic:

- Certain Plastics: CO2 lasers work well with many types of plastic, but not all. Plastics that contain PVC (polyvinyl chloride) or chlorinated materials should be avoided, as they can produce harmful fumes when subjected to the high heat of the laser. Always ensure the plastic being used is safe for laser cutting.

- Thick Plastic Cutting: While CO2 lasers can cut plastic materials, they have limitations in terms of thickness. Extremely thick plastics are better suited for other cutting methods like sawing or milling. CO2 lasers are typically used for materials up to a few millimeters in thickness.

- Highly Reflective or Transparent Plastics: CO2 lasers rely on the absorption of laser energy by the material to cut or engrave. Highly reflective surfaces, such as mirrored plastics, may reflect the laser beam, making cutting difficult. Similarly, transparent plastics may not absorb enough energy for effective cutting or engraving.

- Complex 3D Shapes: CO2 lasers are most effective when working with flat or slightly curved surfaces. Highly irregular or three-dimensional plastic shapes may not be suitable for laser processing, as the laser's focus may vary across the surface.

CO2 lasers are versatile tools for plastic fabrication and customization, offering precision cutting, engraving, and marking capabilities. However, their effectiveness depends on the type of plastic material and the specific project requirements. Understanding the compatibility and limitations of CO2 lasers with plastic is essential for achieving successful results in plastic-related applications.

What a CO2 Laser Can Do with Metal:

- Marking and Engraving: CO2 lasers can mark metals through a process called annealing or etching. This involves heating the metal surface to create a permanent, often contrasting mark. This method is suitable for labeling metal parts, adding serial numbers, or creating decorative designs.

- Surface Cleaning: CO2 lasers can remove contaminants or oxides from the surface of metals, resulting in a clean and polished finish. This is particularly useful in applications where a pristine surface is required before subsequent processes like welding or bonding.

- Surface Texturing: CO2 lasers can create textured patterns or designs on metal surfaces. This is often used for decorative or aesthetic purposes, such as creating unique surface finishes on jewelry or artistic metalwork.

- Cutting Thin Metal Foils: While not the primary application of CO2 lasers, they can cut thin metal foils (typically less than 1mm thick) with limited success. However, this process is slow and not as precise as other metal cutting methods.

What a CO2 Laser Can't Do with Metal:

- Cutting Thick Metal: CO2 lasers are not suitable for cutting thick metal materials. The high-power fiber lasers or plasma cutters are more appropriate for cutting thick metal sheets or structural components.

- Welding or Joining: Unlike other types of lasers such as fiber lasers, CO2 lasers are not used for welding or joining metal pieces. Welding and joining require higher energy densities and specific laser wavelengths, which CO2 lasers do not provide.

- Hardened or Highly Reflective Metals: CO2 lasers are less effective when working with hardened metals or highly reflective surfaces. Hardened metals are more resistant to laser energy, and reflective surfaces can cause energy to be reflected away rather than absorbed for cutting or engraving.

- Intricate Cuts or Complex Shapes: CO2 lasers may struggle with intricate or fine cuts in metal. The precision required for intricate metalwork is better achieved with laser types specifically designed for metal cutting, like fiber lasers.

CO2 lasers have limited applications when it comes to working with metals, primarily focusing on marking, engraving, surface cleaning, and surface texturing of thin metal materials. For more substantial metal cutting, welding, or intricate metalwork, other laser types, such as fiber lasers or specialized equipment, are better suited due to their specific capabilities and energy densities. Understanding these limitations and choosing the right tool for the job is essential for achieving successful results in metalworking applications.

What a CO2 Laser Can Do with Leather:

- Precision Cutting: CO2 lasers excel at precise leather cutting. They can cut intricate patterns, shapes, and designs with remarkable accuracy. This precision is invaluable for creating custom leather goods, intricate leather art pieces, or precise leather components for various applications.

- Engraving and Etching: CO2 lasers are proficient at engraving or etching designs, text, and images onto leather surfaces. This is commonly used for adding decorative elements, personalization, or branding to leather products, whether it's leather goods, accessories, or artwork.

- Scoring and Creasing: CO2 lasers can score or crease leather surfaces, making it easier to fold or bend the material. This is particularly useful for creating leather packaging, leather boxes, or any leather items that require precise folding lines.

- Customization: CO2 lasers offer a high degree of customization. Leather items can be personalized with unique designs, logos, or text, making them one-of-a-kind and catering to specific customer preferences.

What a CO2 Laser Can't Do with Leather:

- Dyeing or Coloring: CO2 lasers cannot dye or color leather. While they can create contrasting effects through engraving or etching, they can't apply color directly. Coloration is typically done using traditional leather dyes, paints, or stains after laser processing.

- Complex 3D Shaping: CO2 lasers are best suited for working with flat or slightly curved leather surfaces. Highly irregular or three-dimensional leather shapes may not be suitable for laser processing, as the laser's focus may vary across the surface.

- Thick Leather Cutting: CO2 lasers have limitations when it comes to cutting thick leather. They are better suited for thinner leather materials, such as those used for accessories, clothing, and small leather goods. Thick leather may require other cutting methods like die cutting or clicker presses.

- Certain Leather Types: While CO2 lasers can work with various types of leather, some extremely hard or densely textured leathers may not engrave as cleanly. The effectiveness can vary based on the leather's thickness, density, and surface texture.

CO2 lasers are valuable tools in leatherworking, offering precision cutting, engraving, and marking capabilities. Understanding their capabilities and limitations is crucial for harnessing their potential effectively in leather-related applications. While they can't perform certain tasks like dyeing or shaping complex 3D forms, they significantly enhance the precision and customization aspects of leather craftsmanship, making them a valuable asset in the world of leatherworking.

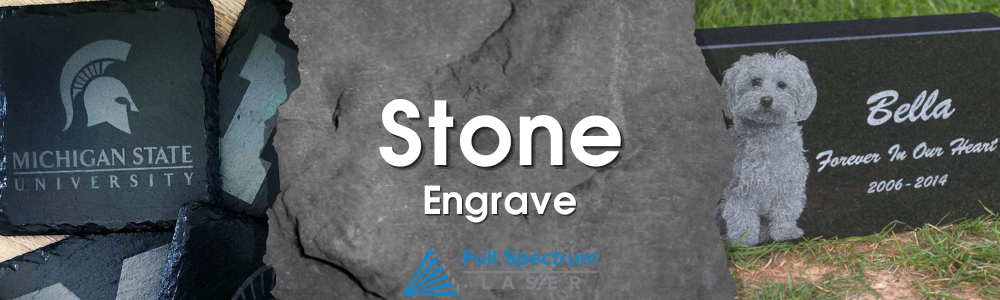

What a CO2 Laser Can Do with Stone:

- Surface Marking: CO2 lasers can create surface markings on certain types of stone, such as marble or granite. These marks are typically light in color and contrast with the stone's natural color, making them suitable for adding text, logos, or simple decorative elements.

- Surface Cleaning: CO2 lasers can be used for surface cleaning on stone. They can remove surface contaminants, dirt, or weathered layers from stone surfaces. This is often used in restoration or conservation projects to reveal the stone's original appearance.

- Surface Texturing: CO2 lasers can add textured patterns or designs to stone surfaces. This is particularly useful for creating decorative stone elements, such as artistic sculptures or architectural details.

- Cutting Thin Stone Sheets: CO2 lasers can cut thin stone sheets, typically up to a few millimeters thick. This is suitable for creating intricate stone inlays or small decorative pieces, such as stone tiles or mosaics.

What a CO2 Laser Can't Do with Stone:

- Deep Engraving: CO2 lasers are not suitable for deep engraving into stone. Their energy levels are insufficient for creating deep or detailed engravings. This task is better suited for specialized stone engraving machines or techniques like sandblasting.

- Heavy Stone Cutting: CO2 lasers are not designed for cutting thick or heavy stone materials. Stone cutting machines that use diamond-tipped blades or water jets are more suitable for such tasks.

- High Precision Intricate Detailing: Achieving high-precision intricate detailing on stone surfaces is challenging with CO2 lasers. The coarse laser beam results in limited detail, making them less suitable for detailed sculptures or complex stone carvings.

- Stone Carving and Sculpting: CO2 lasers are not the tool of choice for traditional stone carving or sculpting. Stone carving typically involves removing large volumes of material, which is better achieved using chisels, grinders, or specialized carving tools.

While CO2 lasers have applications with certain stone materials for surface marking, cleaning, texturing, and cutting thin sheets, they are not the primary choice for deep engraving, heavy stone cutting, intricate stone detailing, or traditional stone carving and sculpting. The choice of tool and technique for stone work depends on the specific project requirements, the type of stone used, and the desired outcome.

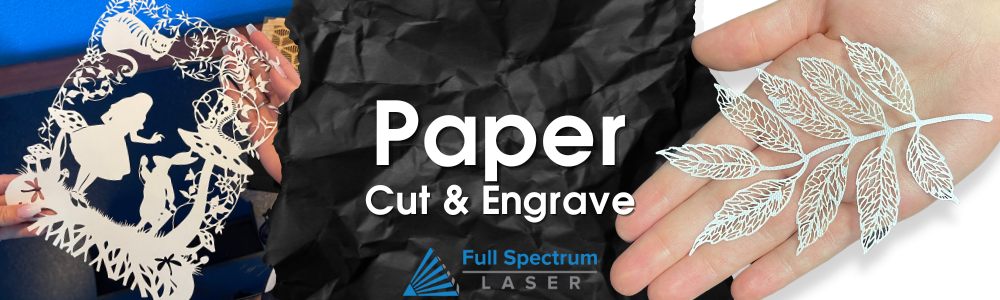

What a CO2 Laser Can Do with Paper:

- Cutting and Perforating: CO2 lasers excel at cutting paper with remarkable precision. They can cut intricate patterns, shapes, and even fine details. This capability is particularly useful for custom packaging, paper art, intricate designs, and precision cutting of paper materials.

- Engraving and Etching: CO2 lasers can engrave or etch intricate designs, text, and images onto paper surfaces. This is often used for adding decorative elements, personalization, or branding to paper products, such as invitations, greeting cards, and stationery.

- Scoring and Folding: CO2 lasers can score paper surfaces, creating precise fold lines. This is valuable for creating folding templates, greeting cards, or packaging with intricate folding patterns.

- Paper Embossing: While not the primary method for embossing paper, CO2 lasers can create embossed patterns or designs on paper surfaces. This is typically achieved by engraving the desired design to a specific depth.

What a CO2 Laser Can't Do with Paper:

- Color Printing: CO2 lasers do not add color to paper directly. They can engrave, cut, or score, but they cannot apply full-color printing like traditional printing presses or inkjet printers.

- Inkjet-like Detailing: While CO2 lasers offer precision, they cannot achieve the fine detailing and color accuracy of inkjet or laser printers. Detailed, high-resolution graphics and photographs are better suited for traditional printing methods.

- 3D Shapes: CO2 lasers are not designed for creating three-dimensional paper sculptures or complex pop-up structures. Such paper art typically involves folding and manually shaping paper.

- Heavy Cardstock Cutting: While CO2 lasers can cut paper with precision, they may struggle with very thick or heavy cardstock materials. Specialized cutting machines or die-cutting tools may be more suitable for heavy cardstock.

CO2 lasers are valuable tools in the paper industry, offering precise cutting, engraving, and scoring capabilities. They are particularly useful for creating custom packaging, decorative paper products, and intricate paper designs. However, they are not a replacement for traditional printing methods when it comes to color printing and fine detailing. Understanding the capabilities and limitations of CO2 lasers is essential for leveraging their potential effectively in paper-related applications.

What a CO2 Laser Can Do with Glass:

- Glass Engraving: CO2 lasers can engrave glass surfaces with precision. This is commonly used for adding intricate designs, text, or images to glassware, such as personalized wine glasses, awards, or decorative glass panels.

- Surface Marking: CO2 lasers can create surface markings on glass. These marks are often light in color and provide a contrasting design or label. This is useful for branding, labeling, or adding decorative elements to glass products.

- Surface Ablation: CO2 lasers can remove the top layer of glass to create a frosted or etched effect. This is commonly seen in decorative glass items, such as privacy windows, glassware, and glass signage.

What a CO2 Laser Can't Do with Glass:

- Glass Cutting: CO2 lasers are not typically used for cutting glass. Glass is highly transparent to CO2 laser wavelengths, which makes it challenging to concentrate enough energy to cut through the material effectively. Specialized glass-cutting techniques, such as diamond or waterjet cutting, are preferred for this purpose.

- Intricate Glass Sculpting: Creating intricate glass sculptures or complex 3D shapes is beyond the capabilities of CO2 lasers. Glass sculpting requires precision tools and methods tailored to the unique properties of glass.

- Glass Fusion: CO2 lasers are not used for glass fusion or glassblowing processes. These processes involve melting and shaping glass at high temperatures, which is entirely different from the precision engraving or marking done by CO2 lasers.

- Coloring or Staining: CO2 lasers cannot color or stain glass. Coloring glass requires specialized techniques such as glass painting, staining, or fusing colored glass pieces.

CO2 lasers can be effectively used for engraving, marking, and creating frosted or etched designs on glass surfaces. However, they are not suitable for cutting glass, creating intricate glass sculptures, or altering the fundamental properties of glass. Understanding the capabilities and limitations of CO2 lasers is essential for utilizing them effectively in glass-related applications.

CO2 lasers are versatile tools for engraving and marking a wide range of everyday items. Here are some common items that can be engraved with a CO2 laser:

- Glassware: CO2 lasers are often used to engrave glass items like wine glasses, beer mugs, and glass trophies. Personalized designs, names, or logos can be added for special occasions or promotional purposes.

- Metal Items: Many metal objects can be engraved with a CO2 laser, such as keychains, dog tags, jewelry, and metal promotional items. The laser can create detailed designs and text on the metal surface.

- Wooden Products: CO2 lasers are excellent for engraving wooden items, including cutting boards, picture frames, wooden boxes, and decorative signs. The laser can produce intricate patterns and text on wood.

- Plastic Items: Plastic products like phone cases, promotional pens, and name badges can be engraved with CO2 lasers. The laser creates precise markings on the plastic surface.

- Paper and Cardstock: Greeting cards, invitations, and other paper products can be customized with CO2 lasers. These lasers can cut intricate designs or engrave text on paper.

- Leather Goods: Leather items such as wallets, belts, and leather journals can be personalized with CO2 lasers. The laser creates detailed engravings and designs on the leather surface.

- Ceramic Tiles: CO2 lasers are used to engrave ceramic tiles for decorative purposes. This is often seen in custom-designed kitchen backsplashes or personalized ceramic coasters.

- Acrylic Products: Acrylic awards, plaques, and promotional items can be engraved with CO2 lasers. The laser creates crisp engravings on the acrylic surface.

- Fabric and Textiles: CO2 lasers can engrave or cut fabric and textiles, which is useful for customizing clothing, textile artwork, or adding labels to textile products.

- Electronics and Gadgets: Electronic devices, laptops, and gadgets often have engraved logos, serial numbers, or labels created with CO2 lasers for branding and identification.

- Barcodes and QR Codes: CO2 lasers are used in industries for engraving barcodes and QR codes on various items for inventory and tracking purposes.

- Medical Instruments: Surgical instruments and medical devices are often engraved with CO2 lasers for traceability, identification, and sterilization purposes.

- Awards and Trophies: CO2 lasers are commonly used to engrave text, logos, and designs on awards, trophies, and plaques to personalize and commemorate achievements.

- Personal Accessories: Everyday personal accessories like watches, eyeglasses, and eyeglass cases can be engraved with CO2 lasers for customization or identification.

These are just a few examples of the many everyday items that can be engraved or marked using CO2 lasers. Their versatility, precision, and speed make them valuable tools for personalization, branding, and customization across a wide range of products and materials.