How Lasers Are Driving the Future of Automotive Fabrication

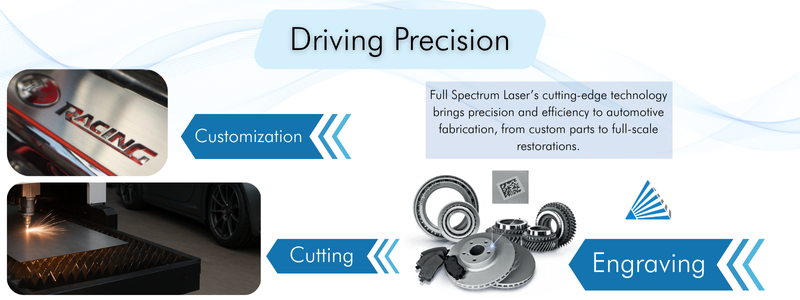

When it comes to the automotive industry, one thing is certain: innovation never slows down. From restoring vintage classics to creating sleek custom builds, shops and manufacturers are always looking for ways to work faster, smarter, and with more precision. That’s where lasers come in.

Full Spectrum Laser has been helping businesses transform their workflows with fiber laser cutters, CO₂ lasers, and automation tools that fit perfectly into the world of automotive restoration, customization, and aftermarket production. And with the SEMA Show in Las Vegas just around the corner, there’s never been a better time to explore how lasers are shaping the future of fabrication.

Fiber Lasers: The Backbone of Automotive Fabrication

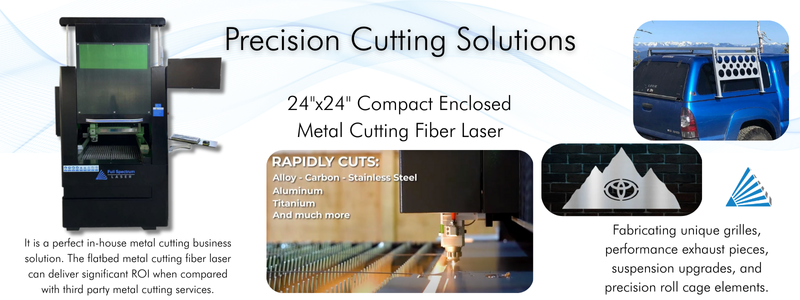

If you’ve ever tried to cut complex metal parts with plasma or a mechanical saw, you know the limitations—rough edges, heat warping, and wasted material. Fiber lasers solve all of that. They cut with incredible accuracy, creating edges so clean they often need no secondary finishing.

For the automotive industry, this is a game changer. Imagine restoring a classic car and needing a discontinued bracket, or fabricating a custom turbo flange that has to fit perfectly the first time. With a fiber laser, you can go from CAD file to finished part in minutes.

Shops use fiber lasers for:

- Restoration: Reproducing hard-to-find brackets, gussets, and panels.

- Customization: Cutting custom grilles, exhaust tips, suspension parts, or roll cage components.

- Performance Upgrades: Making lightweight heat shields, mounting plates, and reinforced engine mounts.

- Branding: Deep-engraving VIN plates, wheel hubs, or calipers with permanent, high-contrast markings.

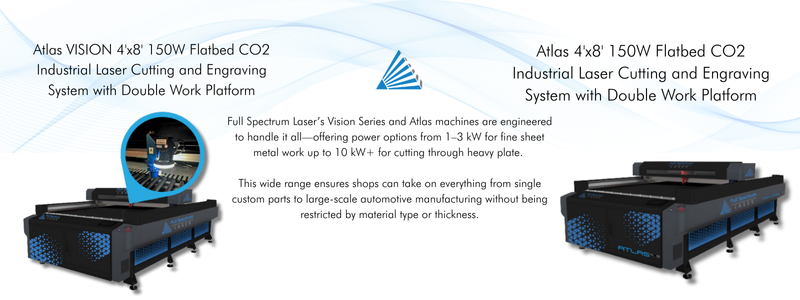

And with different power levels—from 1–3 kW for sheet metal up to 10 kW+ for heavy plate—you’re not limited by material or thickness. FSL’s Vision Series and Atlas machines are built for exactly this kind of work, whether you’re building one-off parts or scaling up production.

Scaling Up: OPS48 Automation

For shops moving beyond one-off custom jobs and into steady aftermarket production, speed and consistency become critical. That’s where OPS48 automation comes in.

OPS48 automatically loads and unloads materials for fiber laser cutters, turning what used to be downtime into production time. For high-volume runs of brackets, trim plates, or decorative overlays, that’s a massive efficiency boost. It means you can take on bigger jobs, meet tighter deadlines, and keep costs under control.

This is the kind of system that lets a small shop scale into a production-ready operation—without sacrificing the precision that makes lasers so valuable.

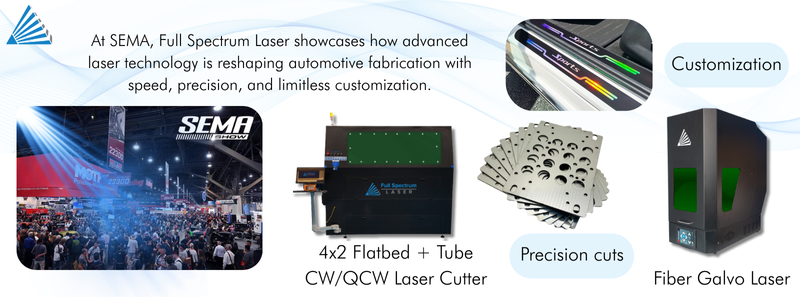

The Power of the 4x2 Flatbed + Tube in Automotive Fabrication

When it comes to automotive fabrication, versatility is everything—and that’s exactly what the 4x2 Flatbed + Tube fiber laser system delivers. With its ability to cut both flat sheet metal and round or square tubing, this machine is a game-changer for shops that need to produce everything from chassis components and roll cages to exhaust systems and custom brackets. Instead of relying on multiple machines or outsourcing tube cutting, the 4x2 streamlines production into one powerful, shop-ready solution. For automotive restorers, custom builders, and aftermarket manufacturers, this means faster turnaround times, reduced waste, and the ability to take on more complex projects with confidence. By combining precision, flexibility, and high-duty performance, the 4x2 Flatbed + Tube is one of the smartest investments a shop can make to stay ahead in the rapidly evolving automotive industry.

The Right Laser for Every Job in Automotive Fabrication

Lasers aren’t one-size-fits-all, and that’s exactly why Full Spectrum Laser offers a complete lineup tailored to every aspect of automotive fabrication. Fiber laser cutters are the go-to solution for cutting and shaping metal components with clean edges and tight tolerances, perfect for brackets, mounts, and performance parts. CO₂ lasers expand the possibilities by working with non-metal materials like wood, fabric, and acrylic—ideal for custom interior panels, displays, or unique shop branding. Meanwhile, galvo lasers excel at fast, detailed marking on metals, making them perfect for engraving logos on anodized aluminum parts, customizing shift knobs, or permanently marking VIN plates and tools. Together, these technologies create an ecosystem that empowers automotive shops to handle everything from precision fabrication to personalization under one roof.

Why Full Spectrum Laser Stands Out

If you’ve looked at competitors like Boss or Bescutter, you’ve probably noticed that many of their machines are geared toward hobbyists or light-duty shops. That’s fine for entry-level work, but the automotive world needs more.

Full Spectrum Laser builds systems designed for serious, shop-grade use—machines that can run day in and day out, delivering the accuracy, speed, and repeatability the automotive industry demands. And with U.S.-based service and training, you’re never left on your own if you hit a roadblock.

The Road Ahead: Lasers at SEMA

The SEMA Show in Las Vegas is the ultimate stage for automotive innovation, and lasers are becoming a must-have tool for shops looking to stay ahead. Whether you’re restoring a classic, building one-off customs, or scaling aftermarket production, lasers open up possibilities that older methods just can’t touch.

At SEMA, you’ll see how FSL’s fiber cutters, CO₂ engravers, and OPS48 automation can take your automotive projects to the next level—faster, cleaner, and with more creative freedom than ever before.

Final Thoughts

The automotive industry is about passion, performance, and precision. With fiber lasers, you can cut any part you need. With CO₂ lasers, you can personalize and elevate interiors and accessories. With OPS48 automation, you can scale up production without missing a beat.

That’s the power of building with Full Spectrum Laser. And if you’re heading to SEMA this year, you’ll see firsthand why FSL is becoming the go-to choice for fabricators, restorers, and customizers across the industry.