Beyond the Bench: How Robotic Arms & Laser Engravers Take Automation to the Next Level

The evolution of modern production is clearly pointing towards increased automation. While laser engravers have already revolutionized precision and detail across numerous sectors, the integration of robotic arms is propelling automation into an entirely new realm, promising near hands-free operation and unprecedented efficiency.

For years, laser engravers have empowered businesses to create intricate designs, process diverse materials with accuracy, and personalize products with ease. But what if you could eliminate the manual steps of loading, unloading, and manipulating materials altogether? That's the transformative potential of combining robotic arms with laser engraving systems – a powerful synergy that's capturing attention across industries.

The Dynamic Duo: Laser Precision Meets Robotic Dexterity

Envision a streamlined process where a robotic arm smoothly picks up a component, precisely positions it under the laser engraver, and then, once the laser processing is complete, effortlessly removes the finished item and places it in a designated area. This isn't a distant dream; it's a tangible reality being implemented in forward-thinking operations.

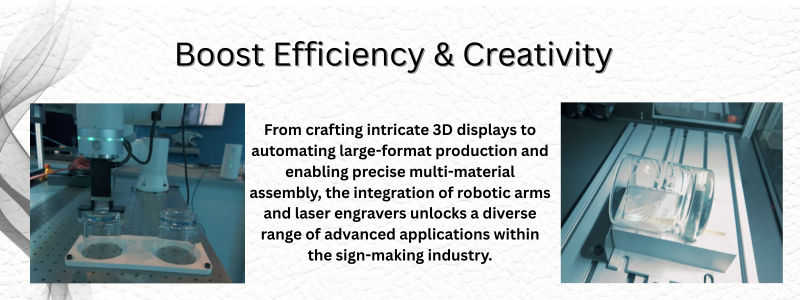

The advantages of this integrated automation are significant:

- True Hands-Free Operation: By automating material handling, you drastically reduce the need for manual intervention, allowing your skilled personnel to focus on design, quality assurance, and strategic tasks.

- Unprecedented Speed and Throughput: Robots operate continuously and consistently. Integrating them with laser engravers dramatically accelerates production cycles, enabling you to handle larger volumes and meet demanding timelines.

- Enhanced Accuracy and Consistency: Robotic arms offer repeatable precision in material placement and orientation, ensuring that every item is processed flawlessly, minimizing errors and waste.

- Safety First: Automating the handling of heavy or awkward materials mitigates the risk of workplace injuries, fostering a safer working environment for your team.

- Flexibility for Complex Tasks: Robotic arms can be programmed for intricate movements and multi-stage processes, enabling the creation of more complex and innovative product solutions.

Full Spectrum Laser: Your Partner in Hands-Free Automation

At Full Spectrum Laser, we recognize the disruptive power of automation across various industries. We're not just providing advanced laser engraving technology; we're developing solutions that pave the way for truly automated production environments.

How can Full Spectrum Laser help you achieve virtually hands-free operation?

- Integration-Ready Laser Systems: Our laser engravers are engineered with automation compatibility in mind, featuring interfaces and protocols that allow for seamless integration with robotic arm systems.

- Custom Automation Solutions: We collaborate closely with our clients to understand their unique operational needs and challenges, offering tailored automation solutions that incorporate robotic arms and our cutting-edge laser technology.

- Software and Control Systems: Our intuitive software facilitates synchronized control of both the laser engraver and the robotic arm, ensuring efficient and coordinated operation.

- Expert Consultation and Support: Our team of automation specialists provides comprehensive guidance and support throughout the entire process, from initial planning to system implementation and ongoing maintenance.

The automation revolution is unfolding across industries right now. Whether you're dealing with high-volume production, intricate processing, or challenging materials, the combination of robotic arms and Full Spectrum Laser engravers offers a clear path toward a more efficient, productive, and ultimately more profitable future.

Ready to explore how you can elevate your automation capabilities and move towards a virtually hands-free operation? Contact Full Spectrum Laser today to discuss your specific requirements and discover the possibilities! The future of automated production is here, and it's powered by precision and robotics.