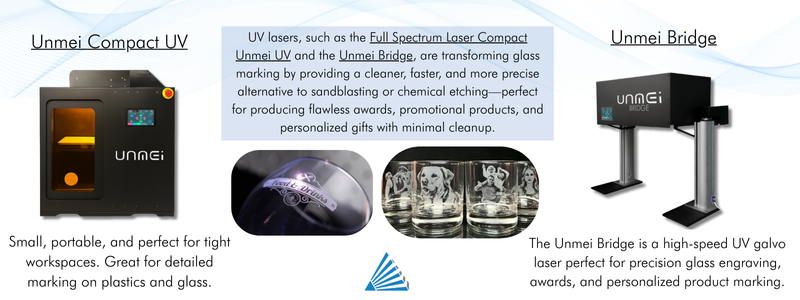

Glass marking has long been a staple for awards, promotional products, and personalized gifts. Traditionally, this process relied heavily on sandblasting, chemical etching, CO₂ Lasers or mechanical engraving. While most of these methods can produce quality results, they are often messy, time-consuming, labor intensive and require extensive cleanup. Enter UV laser technology—a cleaner, more precise, and more versatile solution that’s quickly replacing traditional glass marking methods across a variety of industries.

Why UV Lasers Are Perfect for Glass

UV lasers operate at a wavelength of 355nm, which is ideal for marking glass. This wavelength actually marks the glass through a process called photoablation rather than heat. This process uses high-energy photons to break molecular bonds on the surface without generating excessive heat, preventing cracks, chips, or warping. The process—often called cold marking—ensures flawless, high-contrast results that look sharp and professional.

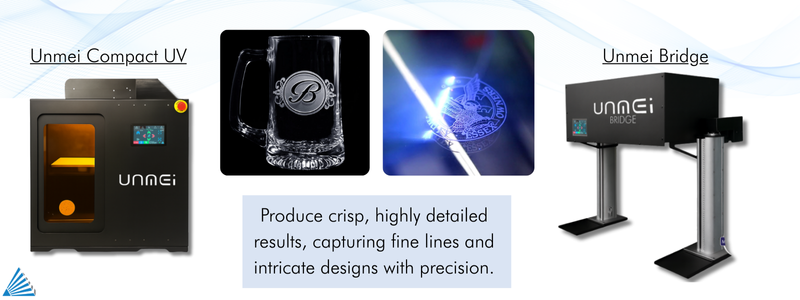

Unlike CO₂ or fiber lasers, UV lasers can achieve extremely fine detail on glass surfaces, making them perfect for intricate logos, text, and even photographic images. This makes them particularly appealing for awards and recognition companies, promotional product suppliers, and specialty gift makers who value quality and aesthetics above all else.

Replacing Sandblasting with Precision

Sandblasting has been a go-to for deep engraving on glass for decades. However, it’s labor-intensive, requires messy abrasive materials, and can be difficult to automate for large-scale production. UV galvo laser systems offer a cleaner, more efficient alternative—producing the same depth and texture without the dust and abrasive grit.

With UV lasers, surface marking or deep engraving on glass can be achieved in a controlled machine driven process. The result is consistent, repeatable, and ready for immediate handling—no masking, blasting, or cleanup required.

CO₂ Laser Engraving on Glass

CO₂ lasers have been used as an alternative to sandblasting and chemical etching for glass engraving, of custom glassware, awards, and decorative projects. It solves some problems, but CO₂ lasers engrave by using intense heat to vaporize the glass surface. This thermal process often causes stress, leading to micro-fractures, chipping, and uneven depths that compromise the glass's durability and clarity. Achieving a clean, uniform mark requires careful power settings and technique, and even then, the results can be inconsistent, especially on delicate or thin glass. For high-precision or deep engravings, UV Lasers deliver better results.

Sub-Surface Laser Engraving: A Game Changer

Beyond surface engraving, UV lasers can also create sub-surface markings inside the glass without altering the outer layer. This technology can produce stunning 3D effects, intricate internal designs, and personalized messages that appear suspended within the glass itself.

For the awards and promotional products industry, sub-surface engraving opens the door to entirely new product categories—high-end trophies, crystal keepsakes, and custom gifts that stand out in a crowded marketplace.

Clean, Compact, and Easy to Use

In addition to performance, UV lasers offer practical benefits that make them ideal for small businesses and boutique shops. Many low-power UV laser systems are compact, self-contained, and air-cooled, making them easy to install in smaller spaces. Higher-power models typically require water cooling for optimal performance, but both options remain cleaner and more efficient than traditional methods.

Setup is plug-and-play for many models, maintenance is minimal, and the operating costs are significantly lower than sandblasting—especially when considering reduced labor costs, the elimination of consumables and cleanup. With modern interfaces and intuitive software, even first-time users can produce professional results in minutes.

A Win for Both Small Shops and Large Production Lines

Whether you’re running a high-volume production line or a small, custom engraving shop, UV lasers scale to meet your needs. Galvo-based UV systems offer blazing-fast marking speeds for bulk orders, while smaller desktop units are perfect for on-demand personalization.

For large manufacturers, the automation potential is huge—integrating UV lasers into conveyor systems or robotic arms for seamless marking on bottles, glassware, and other products. For smaller businesses, the compact footprint and user-friendly setup make it a straightforward upgrade with a quick return on investment.

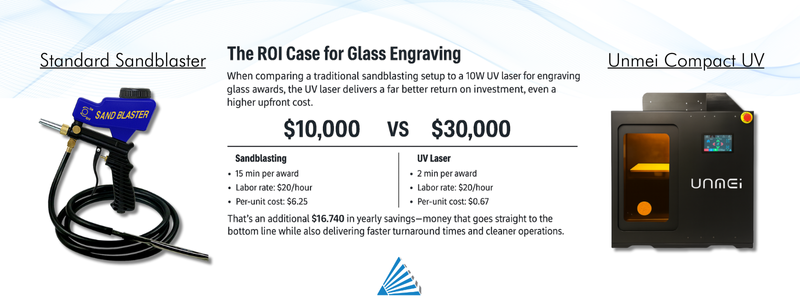

UV Lasers vs. Sandblasting: The ROI Case for Glass Engraving

When comparing a traditional sandblasting setup to a 10W UV laser for engraving glass awards, the UV laser delivers a far better return on investment, even with a higher upfront cost. A professional sandblasting system averages around $10,000, while a comparable UV laser system costs closer to $30,000. Despite the $20,000 difference, the UV laser’s speed and low operating costs quickly close the gap.

At a labor rate of $20/hour, a UV laser can engrave an award in just 2 minutes, with minimal consumables, bringing the per-unit variable cost to about $0.67. In contrast, sandblasting typically takes 15 minutes per award and requires abrasive media, masking materials, and cleanup time—bringing the per-unit cost to roughly $6.25. This $5.58 savings per award means the UV laser pays off its higher initial cost after just 3,584 awards.

For a shop producing 3,000 awards annually, that’s an additional $16,740 in yearly savings—money that goes straight to the bottom line while also delivering faster turnaround times and cleaner operations.

The Bottom Line: UV Lasers Are the Future of Glass Marking

From replacing messy sandblasting to unlocking the potential of sub-surface engraving, UV laser technology is revolutionizing how glass products are decorated, customized, and personalized. It offers precision, efficiency, and cleanliness that older methods simply can’t match—making it the clear choice for awards, promotional items, and beyond.

If your business works with glass, now is the perfect time to explore what UV laser marking can do for you.

UV laser glass engraving, Glass marking technology, Sub-surface laser engraving, CO₂ laser glass engraving, Cold marking on glass, Laser engraving awards, Personalized glass gifts, Promotional product engraving, High-precision glass engraving, Fine detail glass marking, UV laser vs CO₂ laser, Custom crystal engraving, Laser-etched glassware, Compact UV laser systems, Automated glass marking solutions, 3D sub-surface glass engraving, Awards and recognition engraving, Promotional products customization, Boutique glass engraving, Large-scale glass production, Specialty gift engraving