Full Spectrum Laser's New Laser Welder

In the ever-evolving world of metalworking, Full Spectrum Laser has once again set a new benchmark with the release of their state-of-the-art laser welder. This innovative tool is more than just a welder; it’s a versatile powerhouse designed to meet a variety of industrial needs, from precise metal welding to cutting, and even rust and paint removal.

Beyond Traditional Welding

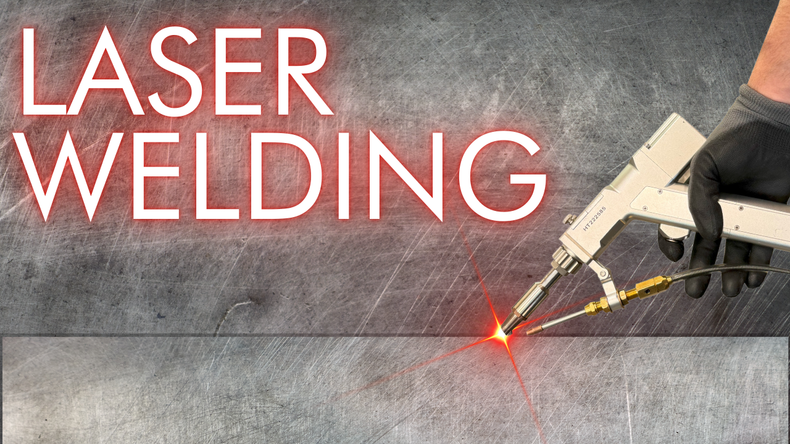

Traditional welding methods have long been a staple in metal fabrication, but they come with limitations in terms of precision, safety, and flexibility. The new laser welder from Full Spectrum Laser breaks through these barriers, offering a seamless and highly accurate welding experience. With pinpoint precision, it can join a wide range of metals, including stainless steel, aluminum, and titanium, with minimal heat distortion.

But welding is just the beginning. What truly sets this laser welder apart is its ability to do more than just fuse metals together.

Versatility Unleashed: Cutting and Surface Preparation

One of the standout features of Full Spectrum Laser's latest offering is its capability to cut through metal with ease. Whether you’re working with thin sheets or thicker materials, this laser welder doubles as a powerful cutting tool, making it an essential addition to any workshop. The clean, precise cuts produced by the laser ensure that your projects maintain a professional finish without the need for extensive post-processing.

Additionally, the laser welder is equipped with a function that allows it to remove rust and paint from metal surfaces efficiently. This feature is particularly useful for restoration projects or preparing metal surfaces for further processing. The laser effectively strips away unwanted layers without damaging the underlying metal, saving both time and effort compared to traditional methods like sandblasting or chemical treatments.

The Game-Changer: Gantry System Accessory

Full Spectrum Laser hasn’t stopped at just creating a multi-functional laser welder. They’ve taken the technology a step further with their innovative gantry system accessory. This addition transforms the handheld metal cutter into a fully-fledged laser CNC machine in seconds. The gantry system allows for automated, computer-controlled operations, bringing a new level of precision and efficiency to metalworking tasks.

With this accessory, users can achieve intricate designs and complex cuts with the consistency and accuracy of a CNC machine, all while utilizing the same laser that functions as a welder, cutter, and surface cleaner. This modular approach not only maximizes the utility of the tool but also offers significant cost savings by eliminating the need for multiple separate machines.

Conclusion

Full Spectrum Laser’s new laser welder is more than just a tool; it’s a comprehensive solution for modern metalworking challenges. With its ability to weld, cut, and clean metal surfaces, combined with the game-changing gantry system that turns it into a CNC machine, this product redefines what’s possible in the industry. Full Spectrum Laser has once again demonstrated its commitment to innovation, providing professionals and hobbyists alike with the tools they need to take their projects to the next level.