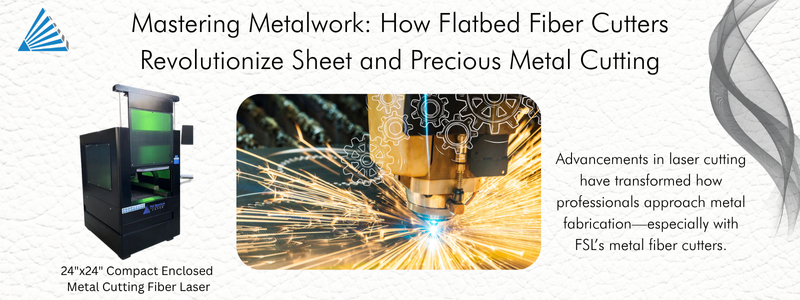

Introduction: Revolutionizing Metal Sheet Cutting

When it comes to cutting metal sheets with accuracy, speed, and efficiency, the flatbed metal fiber cutter stands out as a top solution. Whether you're in industrial manufacturing or crafting intricate designs in the jewelry industry, fiber laser technology delivers clean, precise cuts with minimal waste.

In this blog, we explore the benefits of using flatbed metal fiber cutters for general metalwork and take a closer look at how they serve artisans and manufacturers working with precious metals like sterling silver, pure silver, and gold.

What is a Flatbed Metal Fiber Cutter?

A fiber laser cutting machine operates by generating a high-power laser beam from a bank of diodes, which is then amplified and delivered to the cutting head via a flexible optical fiber. This focused beam melts and vaporizes the material as it moves across the workpiece, while an assist gas (like oxygen or nitrogen) simultaneously blows away the molten material, creating a clean and precise cut. The entire process is controlled by a computer, allowing for intricate designs and high accuracy.

Key Features:

- Exceptional cutting speed

- Energy-efficient operation

- Precision cutting with minimal thermal distortion

- Seamlessly integrated with CAD/CAM software

- Low maintenance costs

Materials Flatbed Fiber Cutters Can Handle

Modern flatbed metal fiber cutters can handle a wide variety of metals, including:

- Stainless Steel

- Aluminum

- Carbon Steel

- Copper

- Brass

- Sterling Silver

- Pure Silver

- Gold

These capabilities make them ideal not just for industrial applications but also for fine metalworking in more delicate industries like jewelry.

Cutting Precious Metals: Jewelry Industry Applications

Sterling Silver and Silver Cutting

Cutting sterling silver (92.5% silver) and fine silver (99.9%) with a fiber laser requires precise control over laser intensity and speed. Jewelry designers often need highly detailed, intricate cuts for components like:

- Custom pendants

- Bracelet links

- Earrings

- Nameplates and engraving blanks

Using a flatbed fiber cutter reduces the risk of warping and preserves the integrity of the metal, even in thin sheets.

Gold Cutting

Gold, being softer and more expensive, requires careful handling. Fiber lasers can be finely tuned to prevent melting or excessive heat marks, making them perfect for:

- Wedding bands

- Intricate filigree

- Name necklaces

- Watch components

Additionally, the low kerf (cut width) helps minimize material loss, which is crucial when working with high-value metals.

Benefits for the Jewelry Industry

- Extreme Precision: Create intricate designs with tight tolerances.

- Speed & Efficiency: Speed up production without sacrificing quality.

- Minimal Waste: Reduces excess material loss—critical when working with precious metals.

- Custom Designs: Easily translate digital sketches into cut-ready files.

- Consistent Quality: Repeat cuts maintain uniformity, which is essential for batch production.

Tips for Using a Flatbed Metal Fiber Cutter on Precious Metals

- Optimize Laser Settings: Use the correct wattage and speed to avoid overheating soft metals like gold and silver.

- Use Protective Film: A thin layer can protect surfaces from scorching or scratches during cutting.

- Clean Metal Surfaces: Dust or oxidation can affect laser performance.

- Test First: Always do a test run with scrap to ensure your settings are dialed in.

Conclusion

Whether you're cutting stainless steel sheets for machinery or crafting bespoke jewelry from sterling silver and gold, a flatbed metal fiber cutter is a versatile and powerful tool. Its ability to handle both heavy-duty materials and delicate precious metals makes it a go-to solution for industries demanding both strength and finesse.