Laser Services: P-Series Alignment Check

Does it seem like your P-Series laser is losing power, especially when it moves further away from the home position? This can be a very frustrating thing to experience, especially if you are in the middle of a job. Well, there’s a chance that your laser machine is out of alignment. In this article, we will summarize the steps needed to check and make sure that your laser machine is aligned properly.

Before you dive into an alignment process, it would be best to double check to see if your laser machine actually needs to be aligned. There are many things that can happen to your laser machine that will make you think that it is out of alignment. All of these are simple fixes, so if you find that one of these laser machine checks fixes your issues, it will save you a lot of time in the long run. You may be using this laser machine to make money for your business, or maybe you’re in a time crunch to get a project done for a friend or family member. Your time is valuable, so these checks will potentially save your time and allow you to focus on the projects that you have to complete.

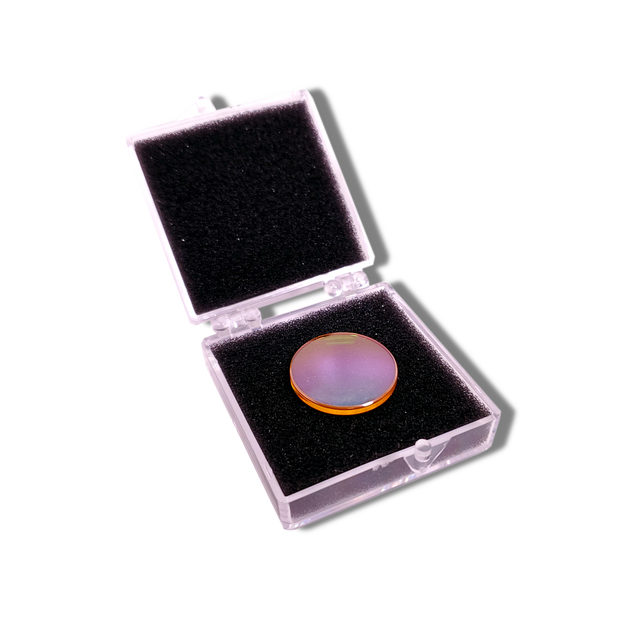

Clean your Optics

The first thing that you’ll want to do is to make sure every part of the optical path of your laser beam is clean. This includes three mirrors, a beam combiner, and your focus lens. It is recommended to always have some optical grade lens cleaning wipes readily available. These are an easy way to clean your optics without needing to have bottles of cleaners and clean microfiber cloths lying around. Clean all the grime and dust off of everything, and make sure your mirrors are 100% reflective. Dust and residue produced from cutting and engraving in your laser system will build up on your optics. Over time, your laser can burn this grime and dust into your mirrors which means you’d have to replace them. Replacing mirrors will mean you’ll have down time as you wait for your mirrors to ship, and then you’ll have to realign the laser after replacement. So using those cleaning wipes frequently will save you the hassle as well as keep you up and running longer.

P-Series Focus Lens, Beam Combiner, and Mirror

Keep your water cool and clean

Make sure the water inside of your chiller is clean. This is a step that can be easy to overlook throughout your maintenance cycles, but keeping the water clean will help ensure that your laser runs at a cooler temperature and will prevent it from wearing out as quickly. The laser tube is a consumable component, so you’ll have to replace this throughout the lifetime of your laser machine, but extending the life of your laser tubes will save you time and money. When you replace your tube, you’ll have to go through the alignment process, so this will save you that time.

CW-3000 Water Chiller

Level your Z-Table

Open the front passthrough door on your laser machine so you can get a better look at the level of the Z-Table. Raise or lower the table so it is at the same level as the back panel and check to see if it lines up perfectly. If it’s not leveled, there will be portions of your project that will be either higher or lower than your focal point, so it will seem like your laser machine is losing power. There are belts and pulleys under the Z-Table that can be easily adjusted to level your table.

Check your alignment

To check the alignment of your laser machine, take a piece of thermal paper and stick it to the end of the nose cone nozzle. Firmly press it in place so you get an impression of the nose cone so you can see where the test fire is coming through the air cone. Make sure your laser machine and the water chiller is powered on. You will want to keep the air assist powered off, since it can blow the piece of thermal paper off of the cone. Now close the lid and do a test fire.

Stick the thermal paper on the tip of the air cone.

Open the laser machine, remove the thermal paper, and examine the test fire. The mark should be mostly round with a tiny pinhole at the center. If your mark looks like it is far off of center, then your laser system needs to be aligned. You may even see a weird crescent shape, or no mark at all. This means that your laser beam is clipping or hitting the side of the nozzle. If this is happening, then your laser machine needs to be aligned. You can follow the link to the article below in order to get instructions on how to align your laser system.

Conclusion

These are some simple steps that will help you save you time and keep your laser firing as optimally as possible. You can perform these steps when you encounter issues, or you can make any of these steps part of your regular maintenance. The P-Series laser systems have a very rigid and durable chassis which helps to keep your optics stable and prevent them from vibrating or moving out of position, so most of the time you will find that these will resolve your issue and that you won’t actually need to perform an alignment.