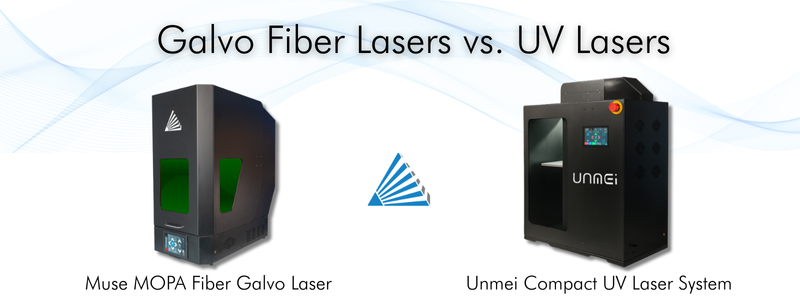

Galvo Fiber Lasers vs. UV Lasers: Which One Is Right for You?

Laser marking technology has evolved rapidly over the past decade, offering advanced options for nearly every type of material and application. Among the most popular choices for precise, non-contact marking are Galvo fiber lasers and UV lasers. While both systems offer exceptional accuracy and speed, they operate on different principles and are better suited for specific types of materials and industries.

If you're trying to decide between the two for your business—whether you're marking medical tools, customizing industrial parts, or labeling electronics—understanding the differences in wavelength, heat impact, cost, and material compatibility is key to making an informed investment.

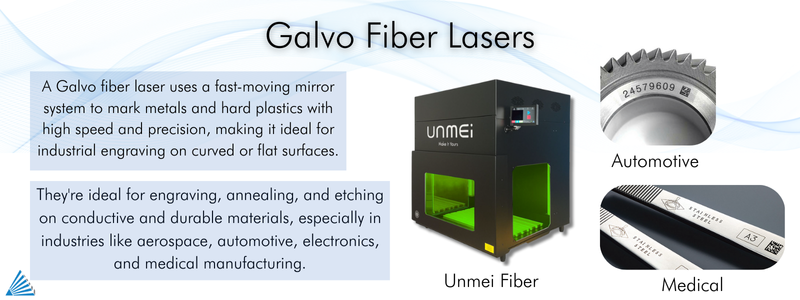

What Is a Galvo Fiber Laser?

A Galvo fiber laser uses a solid-state laser source that emits at a wavelength of 1064 nanometers (nm), making it ideal for metals, ceramics and many industrial plastics. The “Galvo” in its name refers to the galvanometer-driven mirrors that rapidly direct the laser beam across the material's surface. This results in blazing-fast marking speeds—up to 10,000 mm/s or more—with incredible accuracy and repeatability.

What makes fiber lasers particularly appealing is their durability and efficiency. At their core, fiber lasers use solid-state laser diodes, which are very reliable and efficient. These systems often boast lifespans exceeding 100,000 hours. They’re air-cooled, require minimal maintenance, and offer excellent energy efficiency—making them a favorite in metalworking, aerospace, automotive, and tool manufacturing.

You’ll often see fiber lasers used to engrave serial numbers, barcodes, QR codes, logos, or other traceability marks directly onto metal parts. Their ability to etch cleanly even on curved or uneven surfaces gives them a distinct edge for marking complex geometries.

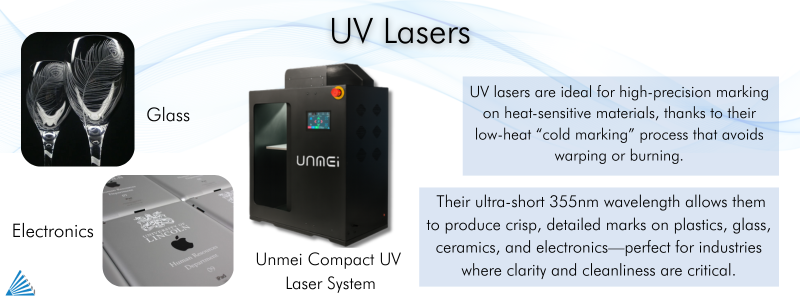

What Is a UV Laser?

UV lasers, or ultraviolet lasers, emit at a much shorter wavelength—typically around 355nm—and operate using a method known as “cold marking.” Unlike fiber lasers, which impart more heat to the material during the engraving process, UV lasers impart significantly lower heat to the part being marked.. This minimizes the heat-affected zone (HAZ) and ensures that even sensitive, delicate materials can be marked without damage.

UV lasers excel when working with plastic, glass, ceramics, silicon wafers, PCBs, paper and other non-metallic or heat-sensitive materials. Their ultra-short wavelength allows them to interact directly with the molecular bonds in many materials, creating high-contrast, high-resolution marks with almost no surface disruption.

Industries such as medical device manufacturing, consumer electronics, packaging, and microelectronics rely heavily on UV lasers for their ability to mark fine details—like text, serial codes, logos, or graphics—on surfaces where any heat deformation or discoloration would be unacceptable.

UV Lasers for Glass Marking: A Game-Changer

One of the most powerful applications of UV laser systems is in glass marking—a fast-growing segment, especially within the awards and promotional products industry. UV galvo lasers offer precise, high-contrast marking on glass surfaces without the need for consumables like sand or masks, effectively replacing traditional sandblasting. With the right settings, UV lasers can even engrave below the surface for stunning 3D effects, ideal for personalized gifts, crystal awards, and high-end branded merchandise. The ability to mark cleanly, deeply, and repeatably on glass makes UV systems an essential tool for businesses looking to stand out with detailed, permanent results.

Key Differences: Galvo Fiber vs. UV Lasers

While both laser systems are highly capable, the core difference lies in how they interact with materials:

- Wavelength & Energy Absorption:

Fiber lasers operate in the infrared range (1064nm), which is efficiently absorbed by metals. UV lasers operate in the UV spectrum (355nm), which is absorbed more readily by plastics and delicate materials. - Heat Input & Marking Impact:

Fiber lasers create heat during the marking process, which can lead to slight deformation if used on soft materials. UV lasers, with their cold marking technique, avoid this entirely, making them ideal for heat-sensitive substrates. - Material Compatibility:

Fiber lasers are best for conductive materials like steel, aluminum, brass, copper, and titanium. UV lasers are designed for non-conductive and delicate materials such as ABS plastic, glass, ceramic, and coated materials. - Cost & Maintenance:

Fiber lasers generally have a lower total cost of ownership, thanks to their longer lifespan and minimal maintenance requirements. UV lasers, while more expensive upfront and slightly more complex to maintain, are indispensable for certain niche applications where other lasers simply fall short.

Application Comparison

When it comes to real-world applications, Galvo fiber lasers and UV lasers excel in different areas based on their core strengths. Galvo fiber lasers are the top choice for metal engraving, offering fast and durable results ideal for industrial part marking, jewelry, and high-volume serial numbering. Their speed and reliability make them perfect for production environments, though their use on plastics is limited and often not suitable for sensitive materials like glass or ceramics.

UV lasers, on the other hand, are the go-to solution for marking plastics, glass, ceramics, PCBs, and other delicate or heat-sensitive materials. Their “cold marking” process ensures no warping or discoloration, making them especially valuable in industries like medical device manufacturing and consumer electronics. While UV lasers may not be effective for deep metal engraving or rapid mass production, they offer unmatched detail and precision where material integrity is critical. Choosing between the two depends largely on your materials, required detail, and production needs.

When to Choose a Galvo Fiber Laser

Choose a Galvo fiber laser if your primary materials are metal, ceramics or hard engineering plastics. If you're producing ID plates, engraving tools, etching part numbers, or marking anodized aluminum, this system is your workhorse. Fiber lasers are also ideal for high-volume environments where speed, durability, and low operational cost are critical.

For small shops and manufacturers with limited space, compact galvo fiber laser systems—like Full Spectrum Laser’s lineup—offer plug-and-play installation and exceptionally low maintenance requirements. With air-cooled options and no consumables, they’re easy to integrate into almost any workflow.

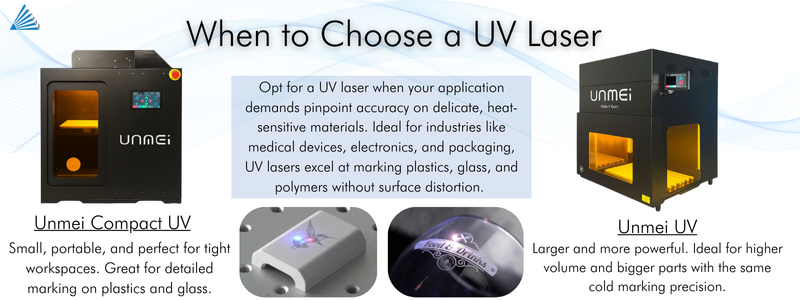

When to Choose a UV Laser

A UV laser is your best option when precision is more important than speed, and when working with sensitive materials is non-negotiable. This includes manufacturers dealing with plastic housings, electronic components, glass containers, or delicate polymer films.

UV lasers are commonly used in the medical, microelectronics, and consumer packaging industries, where fine detail and zero surface damage are essential. Though these systems come at a higher upfront cost, they’re often the only solution for demanding non-metal marking applications.

Final Verdict: Fiber or UV?

In short:

- Go with a Galvo fiber laser if you're engraving metal or need speed and cost-efficiency.

- Choose a UV laser if you're working with sensitive or non-metallic materials that require delicate, high-precision marks.

There’s no universal “best laser”—just the best laser for your specific needs. Many advanced workshops now operate with both systems in-house to cover a full range of materials and marking requirements.

Get Expert Help Choosing Your Laser

At Full Spectrum Laser, we offer both Galvo fiber and UV laser systems tailored for precision, reliability, and long-term ROI. Whether you're a fabricator, an engineer, or a product designer, our team can help you evaluate your needs and match you with the perfect solution.

Or reach out to get a custom quote and answers to all your laser questions.