The laser industry is constantly evolving, and creators are always looking for ways to streamline production, improve quality, and expand creative capabilities. Full Spectrum Laser’s P-Series has already earned a reputation for industrial performance and reliability—but now it’s getting even better. The P-Series lineup is officially LightBurn compatible, bringing one of the most user-friendly and powerful laser software platforms directly into the hands of P-Series users.

A New Level of Workflow Freedom

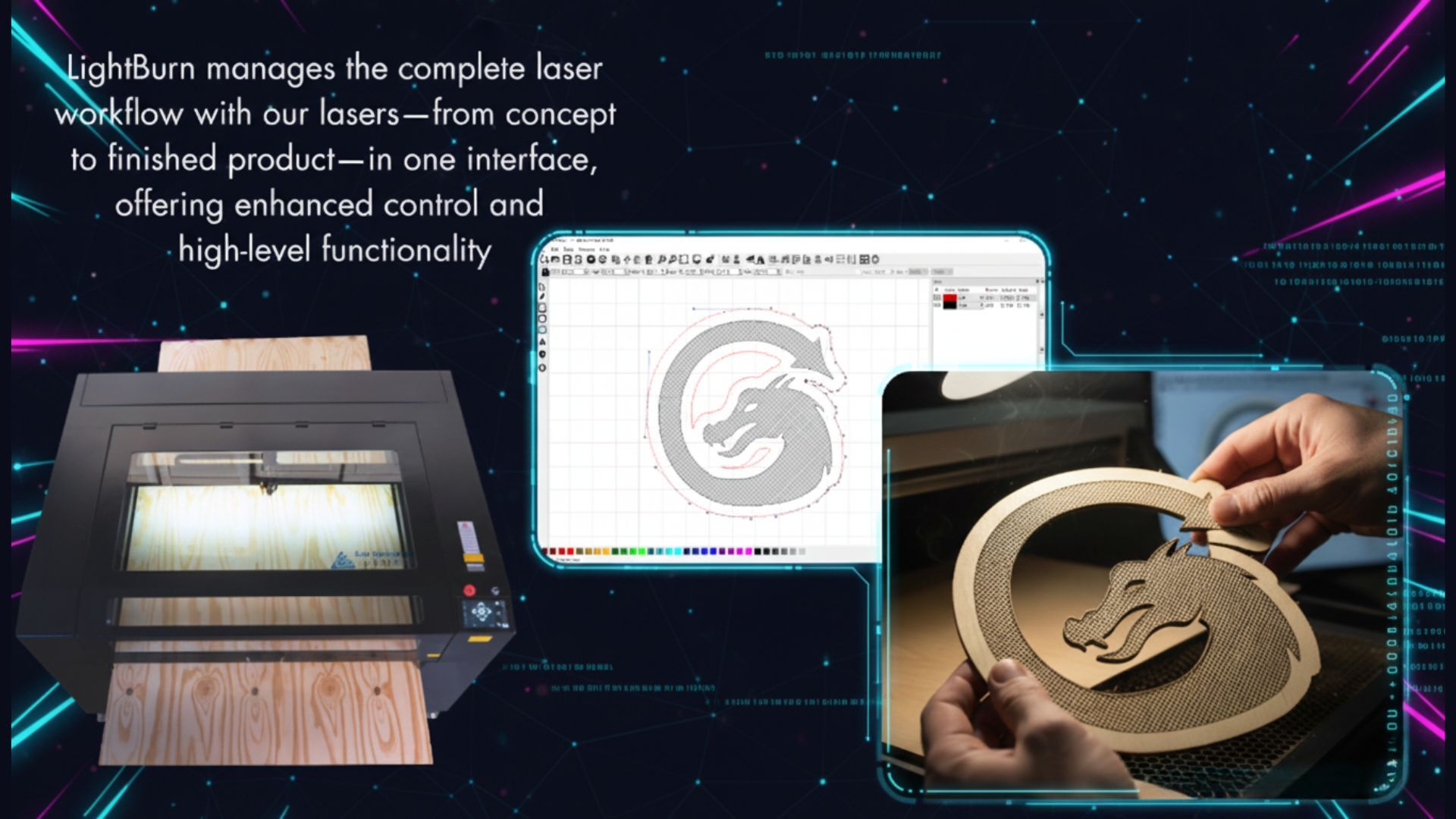

LightBurn is widely known for its intuitive interface, robust design features, and ability to simplify everything from basic cuts to complex engravings. For P-Series owners, this compatibility means a much smoother workflow. Instead of switching between different programs or juggling multiple steps, users can now design, edit, adjust settings, and run their jobs all within LightBurn’s clean and modern interface.

This new level of workflow freedom translates to faster job preparation, fewer errors, and more time spent creating rather than troubleshooting.

Why LightBurn Compatibility Matters

LightBurn’s popularity comes from its ability to handle the entire laser process—from concept to finished product—in one place. The software gives users clearer control over their designs, layers, speed, and power settings while offering advanced tools that many production environments rely on daily.

Bringing that power to the P-Series gives existing users another reason to appreciate their machine, and it opens the door for new users familiar with LightBurn to feel right at home with FSL hardware.

A More Intuitive User Experience

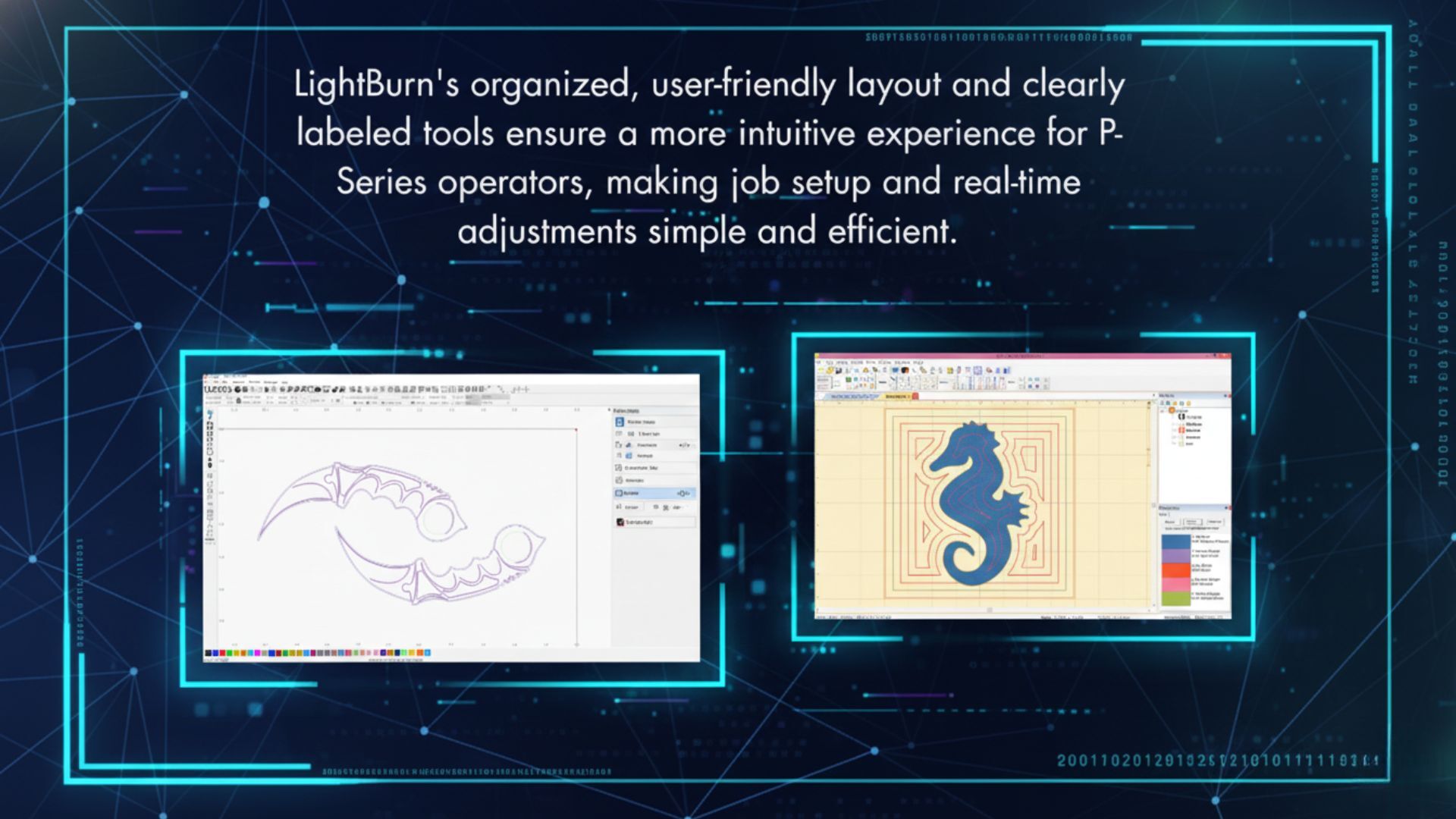

One of LightBurn’s greatest strengths is its user-friendly design. The layout is organized, the tools are clearly labeled, and adjustments can be made in real time. For P-Series operators, this means:

- Faster job setup

- Easy layer organization

- Real-time path previews

- Simple positioning and resizing

- Quick adjustments for speed and power

These features help reduce the friction often associated with preparing laser jobs, especially for new operators or businesses training multiple team members.

Enhanced Image Engraving and Creative Control

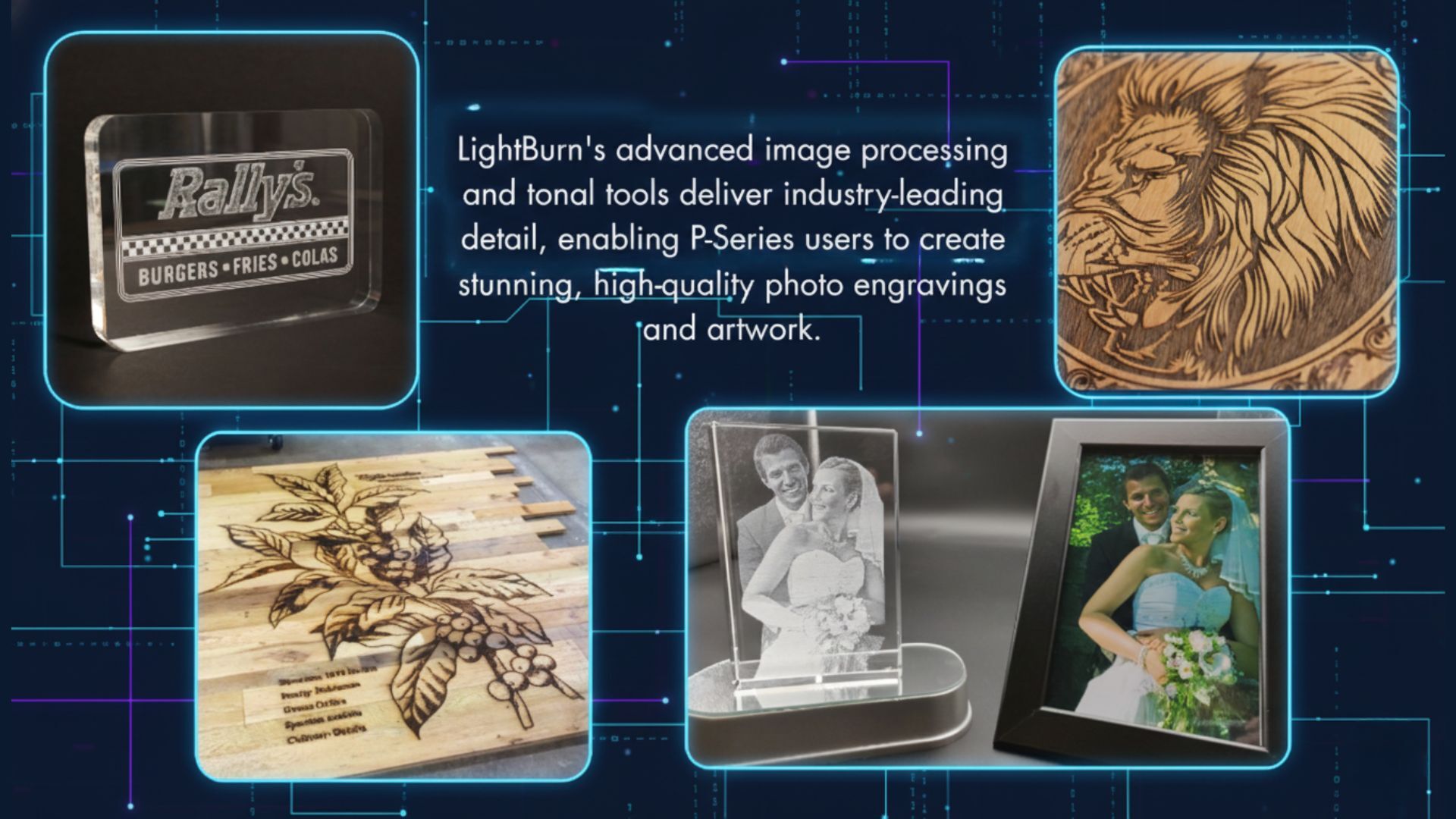

LightBurn’s image engraving tools are among the best in the industry. With advanced image processing, dithering modes, and tonal adjustments, users can create high-quality photo engravings with stunning detail.

When paired with the precision and power of the P-Series, these tools make it possible to engrave:

- Photographs

- Logos

- Artwork

- Textured patterns

- Custom illustrations

Businesses offering custom gifts, tumbler engraving, signage, and detailed artwork will especially benefit from the improved output quality.

Better Training and Easier Onboarding

For businesses that rely on multiple operators, LightBurn compatibility brings another major benefit: easier training. LightBurn is already used across countless laser brands, which means many new hires are likely familiar with it before they even touch a P-Series machine.

This reduces training time, minimizes mistakes, and speeds up how quickly new team members feel confident in running jobs. For production environments, that can mean substantial savings in time and operational efficiency.

Expanding Creative and Business Possibilities

This compatibility update makes the P-Series even more appealing to a variety of users. Small businesses can streamline operations, hobbyists can produce higher-quality work, and professional shops can tackle complex jobs with greater precision.

Real-world applications include:

Custom Product Makers

Easily engrave tumblers, cutting boards, ornaments, and acrylic displays using LightBurn’s advanced image tools.

Sign Shops

Create multi-layered signage with precise cut paths, alignment tools, and power mapping.

Manufacturers

Optimize batch production with predictable engraving paths and easy-tweak design modifications.

Artists and Designers

Quickly transform artwork into engravable designs with node editing, tracing, and path adjustment tools.

These improvements help users take full advantage of the P-Series’ industrial CO₂ laser capabilities.

Why FSL Made the Move

Full Spectrum Laser’s decision to integrate LightBurn support reflects its commitment to growing with the needs of its community. As makers and businesses adopt more flexible workflows, software choice becomes increasingly important.

Offering LightBurn compatibility gives users the freedom to choose the workflow that works best for them, whether they’re designing intricate artwork or running high-volume production.

This update shows that FSL is listening to its users and continuing to support them with tools that evolve alongside the industry.

The Perfect Pairing: P-Series + LightBurn

When hardware and software work together seamlessly, users can focus on what truly matters: creating. The combination of the P-Series’ cutting power and LightBurn’s creative tools results in a system that is both user-friendly and production ready.

Whether you're cutting acrylic, engraving wood, producing signage, or creating custom products, this new compatibility gives you more control, better results, and a more efficient workflow.

Conclusion

The announcement that Full Spectrum Laser’s P-Series is now LightBurn compatible marks a major step forward for both new and existing users. By pairing industrial-grade laser performance with a modern, intuitive software solution, FSL has created a more flexible, creative, and production-friendly environment for makers and businesses of all sizes.

With LightBurn now available as part of the P-Series workflow, users have more freedom, more control, and more opportunities to grow their skills and expand their businesses.