Building a Complete Metal Fabrication Lab with Full Spectrum Laser

In today’s fast-paced world of manufacturing and prototyping, efficiency, precision, and versatility are everything. Small businesses, schools, and industrial fabrication shops alike are discovering the advantages of having a complete fabrication ecosystem under one roof. Instead of piecing together outsourced services or relying on outdated tools, an integrated lab can transform raw sheet metal into finished, production-ready parts—quickly and at scale.

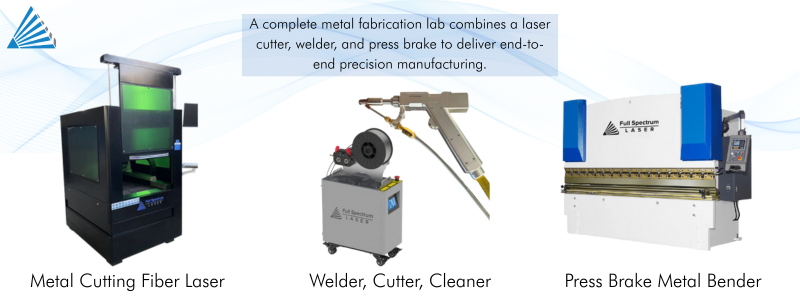

A truly advanced metal fab lab is built around three cornerstone machines: a laser metal cutter, a laser welder/cleaner, and a press brake. Together, they form a streamlined workflow that gives you control from start to finish.

The Power of an Integrated Workflow

A fabrication lab isn’t just about having individual machines—it’s about how they work together. With Full Spectrum Laser’s integrated ecosystem, you can cut metal with micron-level precision, weld or clean parts seamlessly, and then bend them into finished products—all in one continuous process.

This approach eliminates outsourcing delays, reduces rework, and ensures every step of your process is repeatable and reliable. The result? A faster turnaround, lower costs, and the confidence that comes from controlling your own production pipeline.

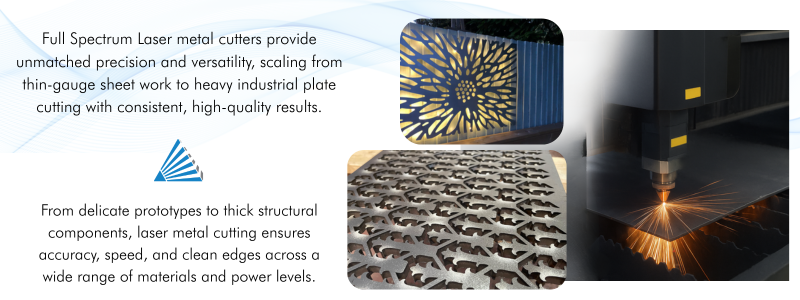

Laser Metal Cutting: Precision from Thin Sheet to Heavy Plate

The laser metal cutter is the cornerstone of any modern fabrication setup. Unlike plasma or mechanical methods, laser cutters deliver fine edges, tight tolerances, and a minimal heat-affected zone—qualities essential for industries where precision matters.

Power Levels and Capabilities

- Low Power (1–3 kW): Cuts thin materials such as mild steel, stainless steel, and aluminum up to about ⅛″ thick. Uses assist gases—oxygen for speed in mild steel, nitrogen for clean, oxidation-free cuts in stainless and aluminum.

- Mid Power (4–8 kW): Handles thicker material, up to ½″ steel and ⅜″ aluminum. Capable of cutting reflective materials like brass and copper with stability.

- High Power (10 kW+): Built for heavy industry, cutting steel beyond 1″ thick and aluminum beyond ½″, at high speeds and with superior edge quality.

Competitor Comparison

BesCutter’s sheet metal cutters range from 1.5 kW to 6 kW, with full enclosure safety and strong throughput for small to medium operations. While these are excellent entry-to-mid tier machines, Full Spectrum Laser offers higher power options that scale to heavy industrial work—giving your lab the ability to grow from prototyping to full-scale production without changing platforms.

Laser Welding and Cleaning: Versatility and Strength

Once your parts are cut, the next step is joining and preparing them. Full Spectrum Laser’s welding and cleaning systems combine three functions in one:

- Welding: Strong, seamless joints with a narrow heat-affected zone to minimize warping.

- Cleaning: Ablates rust, paint, or oxidation without harming the base material.

- Light Cutting: A flexible solution for trimming or cutting thin sheet metal.

Power Considerations

- 1–3 kW systems: Ideal for thin-gauge welding and cleaning applications.

- 4–8 kW systems: Required for thicker or more reflective materials, with deeper weld penetration and faster cleaning.

Wire feeders can also be added—single feeders for gap-filling and reinforcement, or dual feeders for dissimilar metals and higher deposition rates.

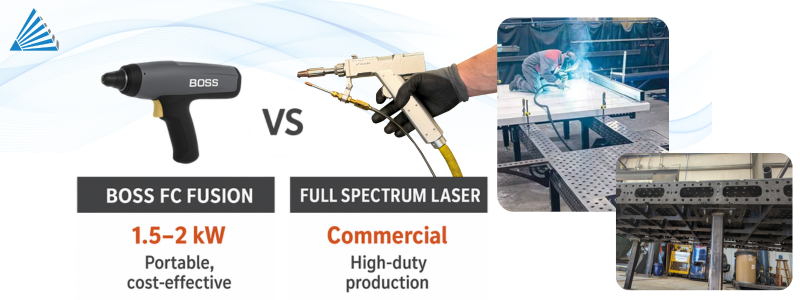

Competitor Comparison

BOSS offers the FC Fusion, a handheld 1.5–2 kW system combining cutting, welding, and cleaning. It’s highly portable and cost-effective, but limited in power and throughput. Full Spectrum Laser’s solutions are designed for continuous, high-duty production—providing a higher return for shops scaling beyond hobby or light industrial use.

Press Brakes: Shaping Flat Sheets into Finished Parts

Cut and welded metal only becomes useful once shaped. A press brake transforms flat sheets into three-dimensional components, from simple brackets to complex housings.

CNC Advantage

Modern CNC press brakes bring precision automation to bending operations:

- Computer-controlled rams and back gauges ensure repeatability.

- Multi-axis configurations enable complex bend geometries.

- Automatic tool changers and bending sequence simulation software streamline setup and production.

- Tonnage ranges vary from ~35 tons for light duty up to 200+ tons for industrial-scale bending.

Competitor Comparison

BesCutter offers CNC press brakes with Delem controls, ranging from servo-driven 40-ton models up to 250-ton units for 10–13′ sheets. While robust, these systems are designed as standalone tools. Full Spectrum Laser’s press brakes are optimized to integrate with your laser cutting and welding workflow, allowing for seamless transitions from cut file to final bent product.

Why Full Spectrum Laser Over Competitors?

When comparing Full Spectrum Laser to competitors like BOSS and BesCutter, the difference lies in integration, scalability, and technical depth:

- Integrated Workflow: Machines designed to work together, not just alongside each other.

- Scalable Power Options: From entry-level prototyping to heavy industrial jobs.

- Higher Throughput: Engineered for continuous duty, not just light-use cycles.

- Unified Control Systems: Software and hardware designed for interoperability.

- Future-Proof Investment: Expand capability without needing to swap platforms.

Final Thoughts: Elevating Your Fabrication Lab

Building a fabrication lab is about more than just acquiring machines—it’s about creating a connected, scalable workflow that grows with your business. Full Spectrum Laser provides the cutting, welding, and bending technology to handle projects ranging from small-scale prototyping to industrial-grade production.

Compared to standalone competitor systems, Full Spectrum Laser delivers integration, power, and efficiency—a complete solution for shops that want professional results without compromise.