Acrylic is a versatile material known for its lightweight, durability, and customizability. One of the most popular methods for working with acrylic is by using a laser machine to engrave intricate designs and perform precise cuts. In this article we will discuss why and how a laser machine is used to cut acrylic as well as how creators assemble their acrylic pieces.

Cutting Your Acrylic Pieces:

Before running a job on your machine, we recommend removing any film or paper that might affect the engraving process, such as a protective film or paper. It is important to note that acrylic materials require lower power settings as excessive heat can cause them to distort. Additionally, acrylic should be cleaned after a job is performed to remove any residue.

Assembling Acrylic Pieces:

While many individuals think of using super glue to assemble their acrylic pieces, there are acrylic bonding agents designed to be used for this purpose, such as acrylic glue, acrylic weld and acrylic cement.

SuperGlue vs Acrylic Bonding Agents:

How do they work?

Most super glues are made using resin, when used the super glue rapidly heats up to bond with the applied surface. Since super glue relies on itself to hold the materials together it is prone to shearing forces and can often leave the acrylic damaged or cracked. Acrylic bonding agents chemically react with the acrylic surface it is applied to, effectively melting and fusing the two pieces together. The bonding agents are easy to apply and leave clear seams when applied correctly.

Where to get them?

Acrylic bonding agents can be found in Amazon or plastic specialty stores. One of the most well known ones is Weld-on, we will prove the link here. We recommend reading the instructions of your bonding agent as each one has different curing times. Additionally the instructions should list the bonding strength of your agent and the types of applications it can be used for.

How to apply your Bonding Agent?

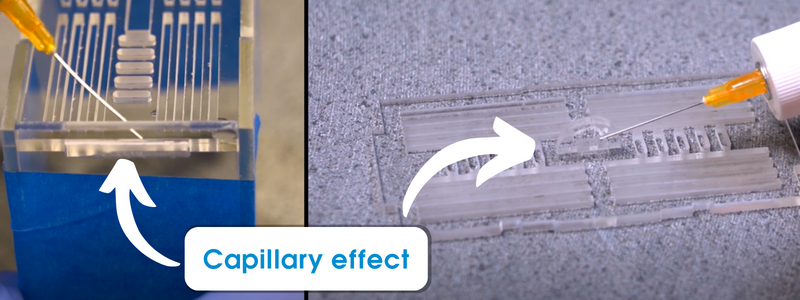

Before applying anything, make sure that the area where the bonding will occur is clean of any dust or debris. When applying the bonding agent make sure the adhesive fills all the seams. The liquid will fill the joints and seams by capillary action, also known as capillary effect. For those unfamiliar with the term capillary action is the movement of liquid through another material. Join your pieces together and let it cure. Remove any excess material using a cotton swab or soft cloth.

Acrylic Fish Tanks:

Many people have started making their own fish tanks using acrylic. Not only is acrylic a light weight material, it is far sturdier and has better insulation than glass. Additionally making your own aquarium is a good idea for individuals that have little to no space as it can be easily customized. If you are a fish keeping enthusiast, maybe you are interested in learning about how aquariums are made. Or if you’ve decided to build your own aquarium, we have the files available here and a video tutorial on making and assembling it on Youtube.

Other Ideas:

If you are interested in other acrylic design we have an acrylic bowl here, some sign ideas here, and a light switch here. For any other ideas on acrylic projects we recommend visiting our Free Project page here to get inspirations. If you're interested in learning how to paint acrylic, we recommend checking out our Youtube video here.

Working with an acrylic bonding agent, such as acrylic cement, to bind laser cut acrylic is an excellent way to create intricate and professional looking products. Whether you're creating one of a kind signage, artistic displays, or sturdy jigs using acrylic bonding agents will create a seamless look. With enough preparation and some attention to detail, you can unleash the full potential of this versatile material.