4x2 + Tube Cutter from Full Spectrum Laser

If you run a fabrication shop, small manufacturing business, or even a growing product development lab, you've probably considered bringing your metal cutting in-house. Outsourcing laser cutting is costly, time-consuming, and often limits your ability to make quick changes or meet tight deadlines. That’s where the 4x2 + Tube Fiber Laser Cutter from Full Spectrum Laser (FSL) shines. This compact yet powerful system combines sheet metal and tube cutting capabilities in a single, easy-to-use platform, designed specifically for smaller workspaces that still demand industrial performance.

What sets the 4x2 + Tube system apart isn’t just its size—it’s the thoughtfully engineered features that make this machine ideal for real-world applications. Fully enclosed for safety and cleanliness, the system is plug-and-play compatible with standard 120V–220V single-phase power. That means no three-phase upgrades or specialized facility requirements, allowing you to drop it into nearly any shop, garage, or maker space. With its powerful fiber laser source, optional configurations from 1.5kW to 6kW, and the ability to handle both flat and tubular metal stock, the 4x2 + Tube gives you complete control over your metal cutting process.

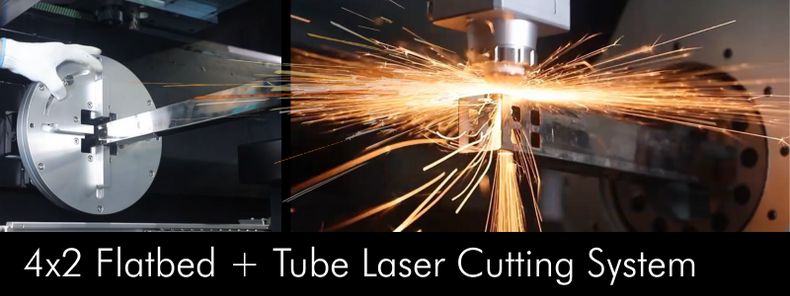

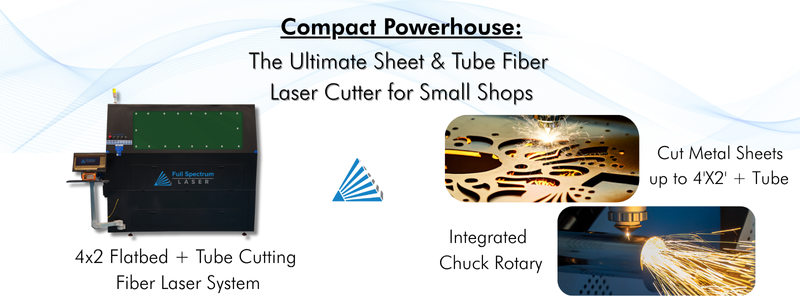

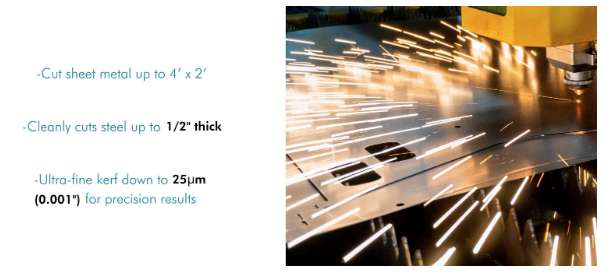

Sheet and Tube Cutting in One Space-Saving Design

One of the standout benefits of the 4x2 + Tube Cutter system is its ability to handle both sheet metal and tubing without requiring separate machines. The flatbed can accommodate sheets up to 4 feet by 2 feet—ideal for most small- to medium-scale production tasks—while the integrated rotary chuck allows for precise cutting of both round and square tubing up to 3 inches in diameter. Whether you're fabricating structural supports, brackets, signage, or cylindrical enclosures, this dual-purpose capability saves time, space, and money.

Beyond convenience, the system delivers exceptional precision. It cleanly cuts materials like mild steel up to half an inch thick and achieves a kerf as narrow as 0.001 inches (25 microns), which makes it well-suited for high-detail applications. Whether you're producing tight-tolerance prototypes, intricate decorative work, or complex mechanical components, the 4x2 + Tube Cutter performs with reliability and repeatability.

QCW Fiber Lasers: Efficiency Beyond Precision

For shops that prioritize precision and efficiency, Quasi-Continuous Wave (QCW) laser systems offer more than just ultra-fine cutting capabilities. A standout advantage of the 1500W QCW fiber laser system from Full Spectrum Laser is its air-cooled design, eliminating the need for a stand-alone chiller.

In fact, QCW systems in general only require cooling at the cutting head itself, significantly reducing the size and complexity of the chiller. This leads to two major benefits for the end user: First, it frees up valuable floor space in your workshop—ideal for smaller shops where every square foot counts. Second, it lowers the overall cost of ownership and operation by minimizing energy consumption and maintenance requirements associated with larger cooling units.

Whether you're cutting jewelry, thin metals, or fine details that demand precise control, the 1500W QCW system offers that precision without the industrial bulk. This makes it a smart choice not only for detailed applications but also for operations looking to scale intelligently with reduced overhead.

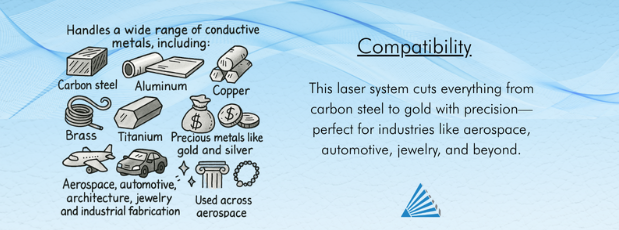

Engineered for Multi-Metal Mastery

Another major advantage of this fiber laser system is its broad compatibility with conductive metals. From common shop materials like carbon steel, stainless steel, and aluminum to more specialized metals like brass, copper, titanium, and even precious metals like gold and silver, the 4x2 + Tube Cutter is ready to meet your material needs. This makes it an ideal choice for businesses working across industries such as aerospace, automotive, industrial manufacturing, jewelry design, and architectural metalwork. If your projects demand flexibility in materials, this machine has you covered.

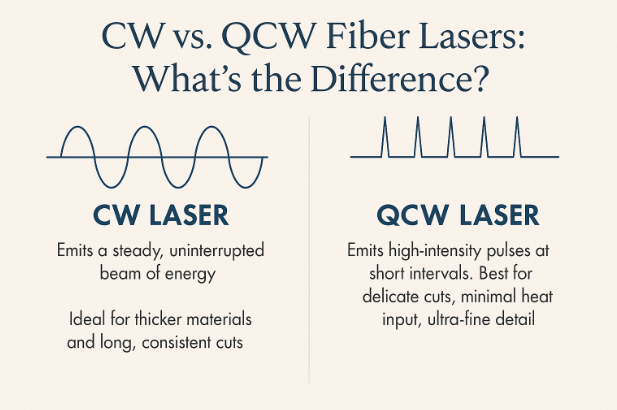

CW vs. QCW Fiber Lasers

Depending on your application, you may need to decide between a Continuous Wave (CW) and a Quasi-Continuous Wave (QCW) laser configuration. CW lasers emit a steady, uninterrupted beam of energy, which is ideal for thicker materials and long, consistent cuts. These are perfect for general fabrication shops and production lines that need speed and reliability.

On the other hand, QCW lasers emit high-intensity pulses at short intervals. This configuration is best suited for applications requiring delicate cuts, minimal heat input, or ultra-fine detail—such as jewelry making, electronics prototyping, or intricate decorative work. QCW allows for greater control over the heat-affected zone and can help prevent warping in thinner materials. Whether you prioritize throughput or precision, Full Spectrum Laser offers both options so you can tailor your system to your specific workflow.

No-Hassle Power Requirements

One of the biggest barriers to adopting industrial equipment in a smaller shop is the need for high-voltage, three-phase power. Thankfully, the 4x2 + Tube Cutter system is designed to operate on standard 120V to 220V single-phase power, making installation simple and cost-effective. You won’t need to upgrade your electrical system, which significantly reduces the total cost of ownership and allows for a faster return on investment. Just plug it in and start cutting.

Safety, Cleanliness, and Low Maintenance

Safety is built into every part of the 4x2 + Tube Cutter’s design. The system is fully enclosed, protecting users from laser radiation and stray debris. This enclosure also keeps the work area clean and minimizes noise and fumes—especially important when operating in smaller or shared spaces. In fact, cutting metal typically produces fewer odors and particulates than cutting materials like wood or plastic, making this an even cleaner solution. On top of that, fiber lasers require far less maintenance than older CO2 systems, resulting in fewer downtimes and lower operational costs.

Who Is This System Built For?

The versatility and compact design of the 4x2 + Tube Fiber Laser Cutter make it an excellent choice for a wide range of users. Whether you're running a custom fabrication shop, developing prototypes in a research lab, or managing a small-scale manufacturing facility, this machine gives you the performance you need without the footprint you don’t. It’s also a perfect fit for interior designers, architects, and anyone in the aerospace or automotive sectors who need reliable, repeatable metal cutting without the expense and infrastructure of a traditional industrial laser cutter.

Take Control of Your Workflow and Profit Margins

If you've been outsourcing your metal cutting needs, you already know how expensive and inconvenient it can be. With service costs often exceeding $300 per hour, the ability to cut your own parts in-house can have a dramatic impact on your bottom line. The 4x2 + Tube Fiber Laser Cutter from Full Spectrum Laser not only reduces your operating costs but also gives you full control over your production timeline and quality assurance.

From rapid prototyping to full-scale manufacturing, this machine is built to grow with your business. It shortens lead times, expands your service offerings, and helps you meet customer demands faster. The compact footprint, wide material compatibility, and flexible power requirements make it a smart long-term investment for any metal-focused operation.

Ready to Get Started?

If you're looking to bring precision metal cutting in-house without sacrificing quality or breaking the bank, the 4x2 + Tube Fiber Laser Cutter is your answer. Learn more, compare models, or request a quote at fslaser.com. Join thousands of businesses already taking their production to the next level with Full Spectrum Laser.