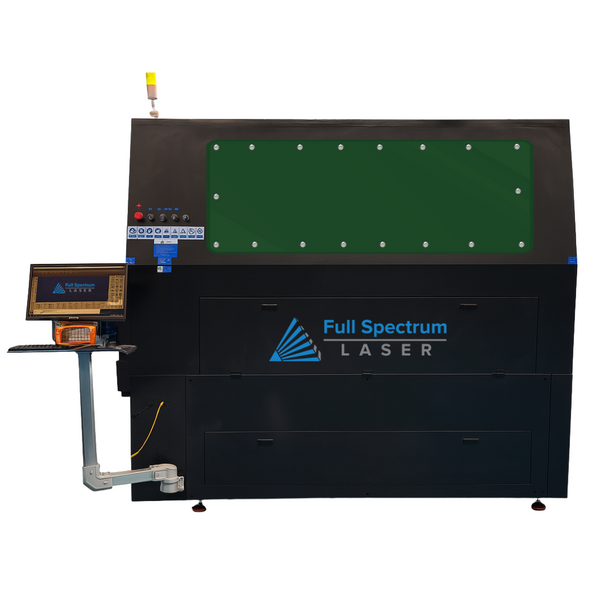

Product Overview

Dual 4x2 Flatbed + Tube CW/QCW Laser Cutter

State of the Art:

- Laser Source: Solid State 1064nm Fiber Laser offered in CW and QCW options

- Laser Power: 1.5kw - 6kw options available

- QCW option provides precision cuts with minimized heat affected zone for small features that would otherwise be melted together

- 110-220V single phase (QCW and CW < 2kW)

- Fully Enclosed for Safety: 57" deep x 93" long x 86" tall (smaller size available for lower power models)

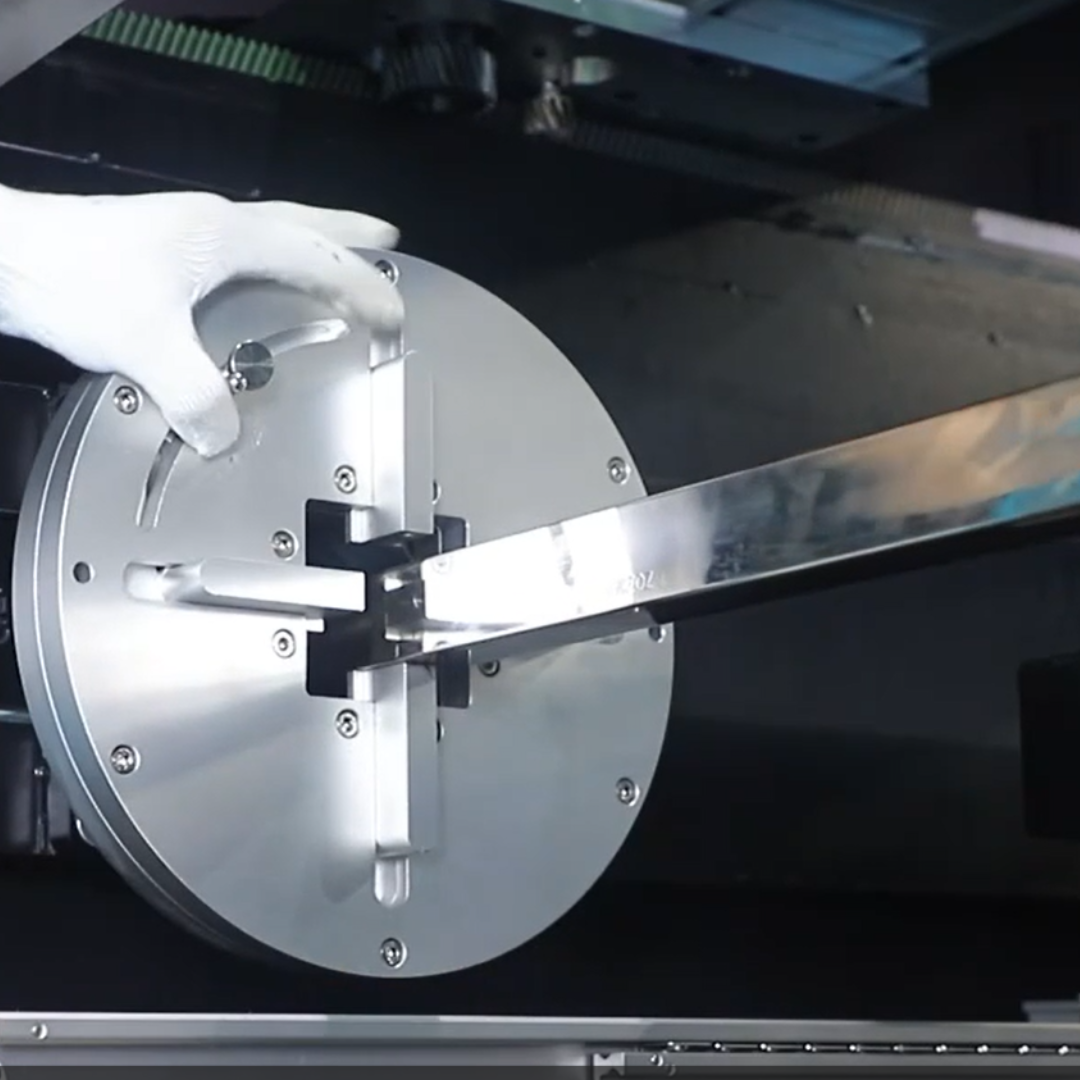

- Integrated Tube Cutter: swap between flat and tube stock in <30sec

- Cut pipe & square tubing with tube chuck up to 18" (3" internal clamp)

Compact. Powerful. Profitable.

Looking for a cost-effective, compact fiber laser cutter that delivers industrial-grade performance? The 4x2 + Tube Fiber Laser Metal Cutting System is the ultimate in-house solution for precision cutting of sheet metal and tubing — all without the need for three-phase power.

This fully enclosed, low-maintenance system offers unmatched versatility, safety, and ROI, making it the ideal laser cutter for small shops, manufacturers, and fabrication businesses.

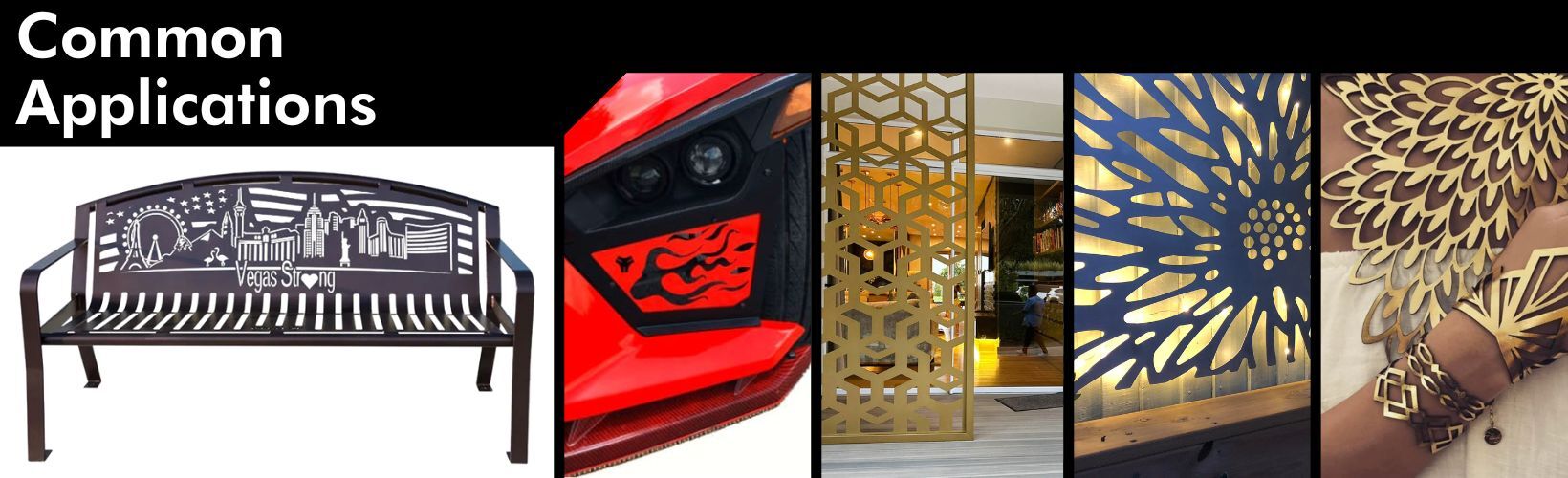

- Sheet Metal Fabrication

- Automotive Industry

- Aerospace Industry

- Architectural and Interior Decoration

- Electrical and Power Equipment Manufacturing

- Commercial Kitchen Equipment

- Agricultural Machinery

- Advertising and Signage

- Medical Device Manufacturing

Key Features

|

Integrated Chuck Rotary, Holds Square and Round Tubing up to 3" Diameter |

|

Fast and Precise Metal Tube Cutting.

|

|

|

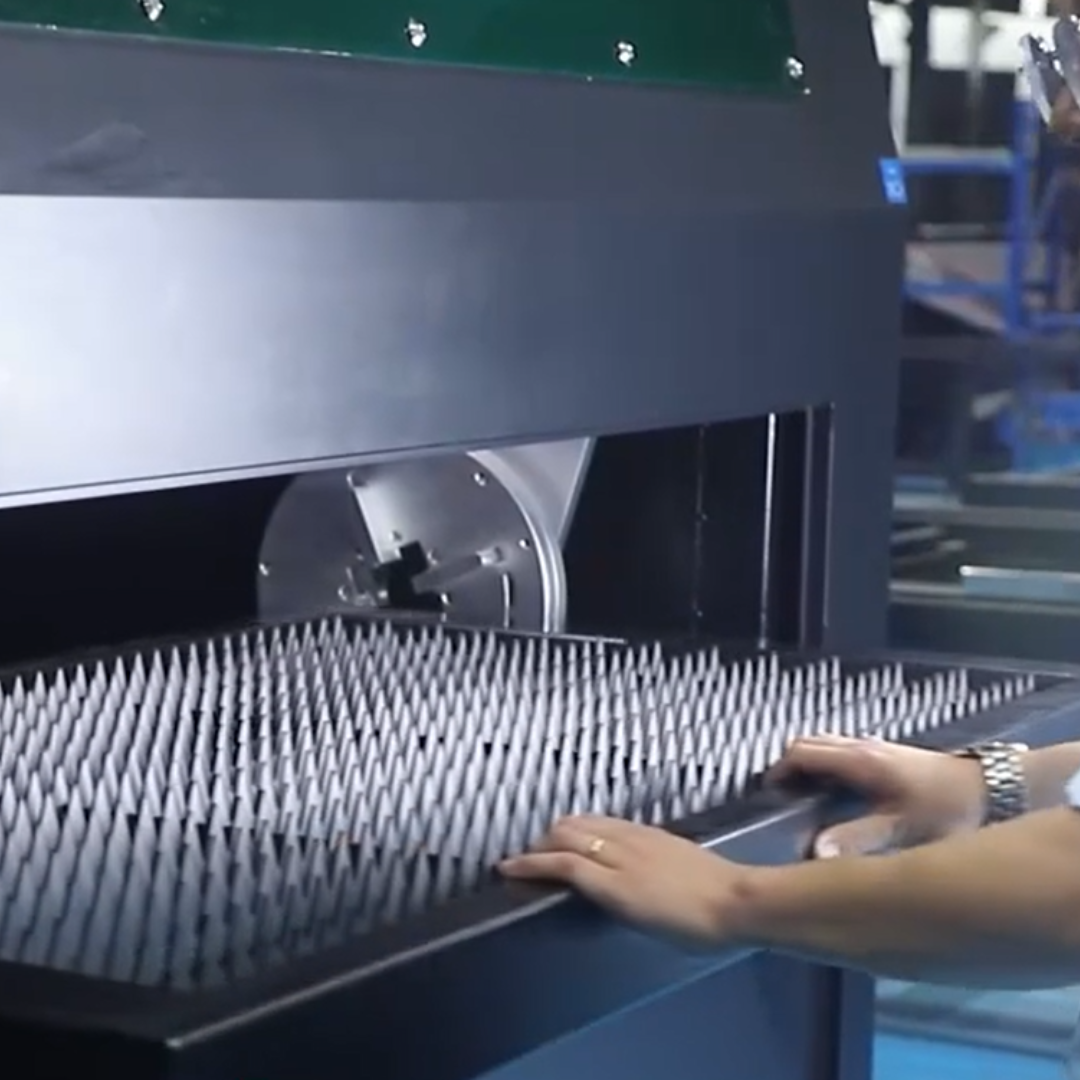

Roll out cutting table for easy loading of material Convert between tube and flat cutting instantly |

|

Cut sheet metal up to 4’ x 2’

|

|

- Cut flat sheet metal up to 4’ x 2’

- Integrated rotary chuck cuts round and square tubing up to 3” in diameter

- Convert between tube and flat cutting by sliding table back

High-Performance Cutting

- Cleanly cuts steel up to 1/2" thick

- Ultra-fine kerf down to 10 microns (0.0004") for precision results

- Power options from 1.5kw to 6kw

- CW and QCW options, QCW offers lowest heat affected zone for precision cuts

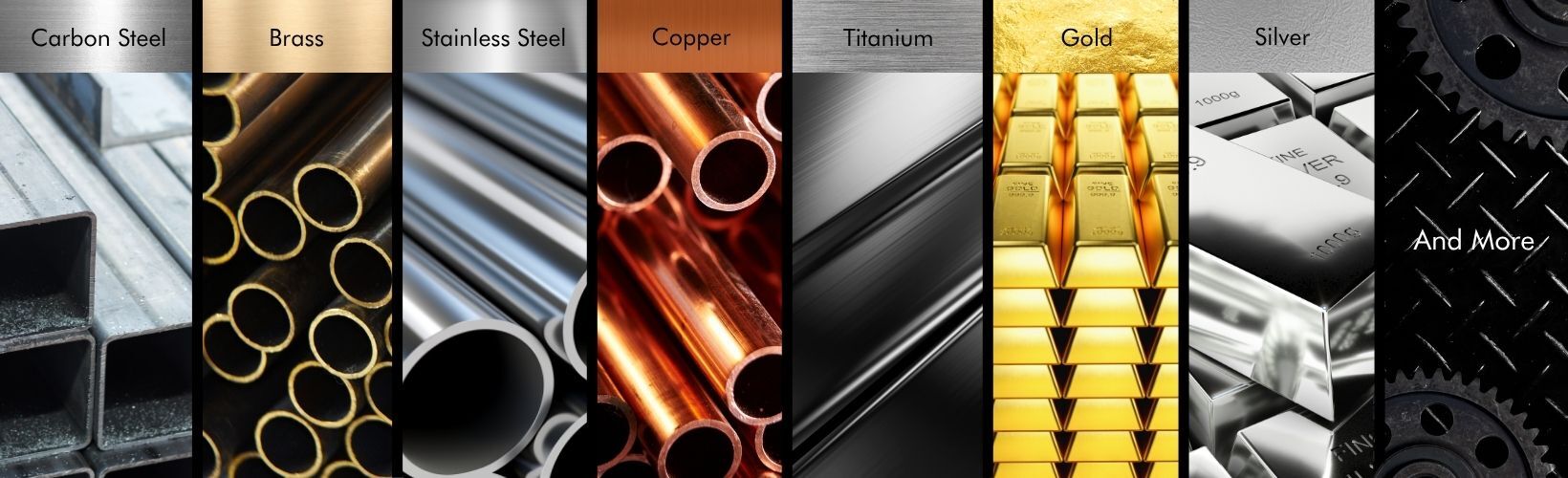

Multi-Material Compatibility

- Cuts carbon steel, stainless steel, aluminum, copper, titanium, gold, silver, and more

- Ideal for metals commonly used in aerospace, automotive, and architecture, Jewelry

Plug & Play Power

- Operates on standard 120V–220V single-phase power

- No three-phase installation or electrical upgrades required

Efficient and Safe Operation

- Small footprint can be accommodate in even the smallest of shops:

- Fully enclosed cutting area ensures operator safety

Produces minimal odor and fumes—cleaner than wood or plastic laser cutting

Ideal For:

- Custom fabrication shops

- Small-to-medium manufacturing operations

- Prototyping and product development

- Architectural and decorative metalwork

- Automotive and aerospace component fabrication

- Schools and makerspaces

Multi-Material Compatibility

Comparison Chart: Quasi-Continuous Wave (QCW) VS Continuous Wave (CW)

| Feature | QCW | CW |

|

Cut Quality

|

Deeper, cleaner cuts with reduced thermal distortion and spatter; smoother edges. | Good for general cutting, but can lead to more thermal stress and distortion. |

|

Peak Power

|

Significantly higher peak power (often 10x+ average power) for concentrated energy. | Lower peak power; constant energy delivery. |

|

Heat Input

|

Minimized heat input due to pulsed operation; smaller HAZ, less distortion. | High, continuous heat input; larger Heat-Affected Zone (HAZ). |

|

Speed

|

Often faster for thin to medium materials and intricate cuts due to rapid piercing and precise control. | Generally faster for thick materials where deep, continuous penetration is key. |

|

Cooling

|

Lower power sources can be air-cooled; higher power sources are often water-cooled but require less cooling than typical CW. | Typically water-cooled due to high and continuous heat generation. |

|

Material Suitability

|

Ideal for thin or reflective materials (e.g., copper, aluminum) and heat-sensitive alloys. | Better for thicker materials and those less sensitive to heat. |

|

Power Requirements

|

Single phase power | Single phase below 2kW, 3 phase above 2kW |

|

Pricing

|

Often higher initial cost for comparable average power due to complex pulsing technology, but can be more cost-effective for specific applications (e.g., reflective materials). | Generally lower initial cost for basic cutting machines, especially at lower to medium power levels. |

❓ Frequently Asked Questions (FAQ)

Q: Can this laser cutter handle both flat sheets as well as round and square tubing?

A: Yes! It features a 4’ x 2’ cutting bed as well as an integrated rotary tube chuck that accommodates square and round pipes up to 18” in diameter (3" with internal clamping). Simply push the table back to switch modes - no refixturing needed!

Q: What kind of power does it require?

A: It runs on standard 120V–220V single-phase power, making it perfect for shops without three-phase service.

Q: What assist gas does it require?

A: QCW can run regular compressed air for nitrogen gas savings. CW uses Oxygen or Nitrogen.

Q: What materials can it cut?

A: This fiber laser is compatible with steel, stainless, aluminum, copper, brass, titanium, silver, gold, and most other metals.

Q: Is this a good solution for small fabrication shops?

A: Absolutely. It's a compact, affordable, and low-maintenance system perfect for small to mid-size businesses looking to bring metal cutting in-house.

Take Control of Your Metal Cutting

The 4x2 + Tube Fiber Laser Cutter combines industrial precision with shop-friendly power and price. Whether you're cutting sheet metal, square tubing, or round pipe, this system helps you scale your business, reduce costs, and increase control over your production pipeline.

Contact us today to request a quote, get a demo, or learn more about how our fiber lasers can help grow your business.